|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

FRONT DIFFERENTIAL CARRIER ASSEMBLY MAINTENANCE - CONTINUED

0296 00

ADJUSTMENT

1.

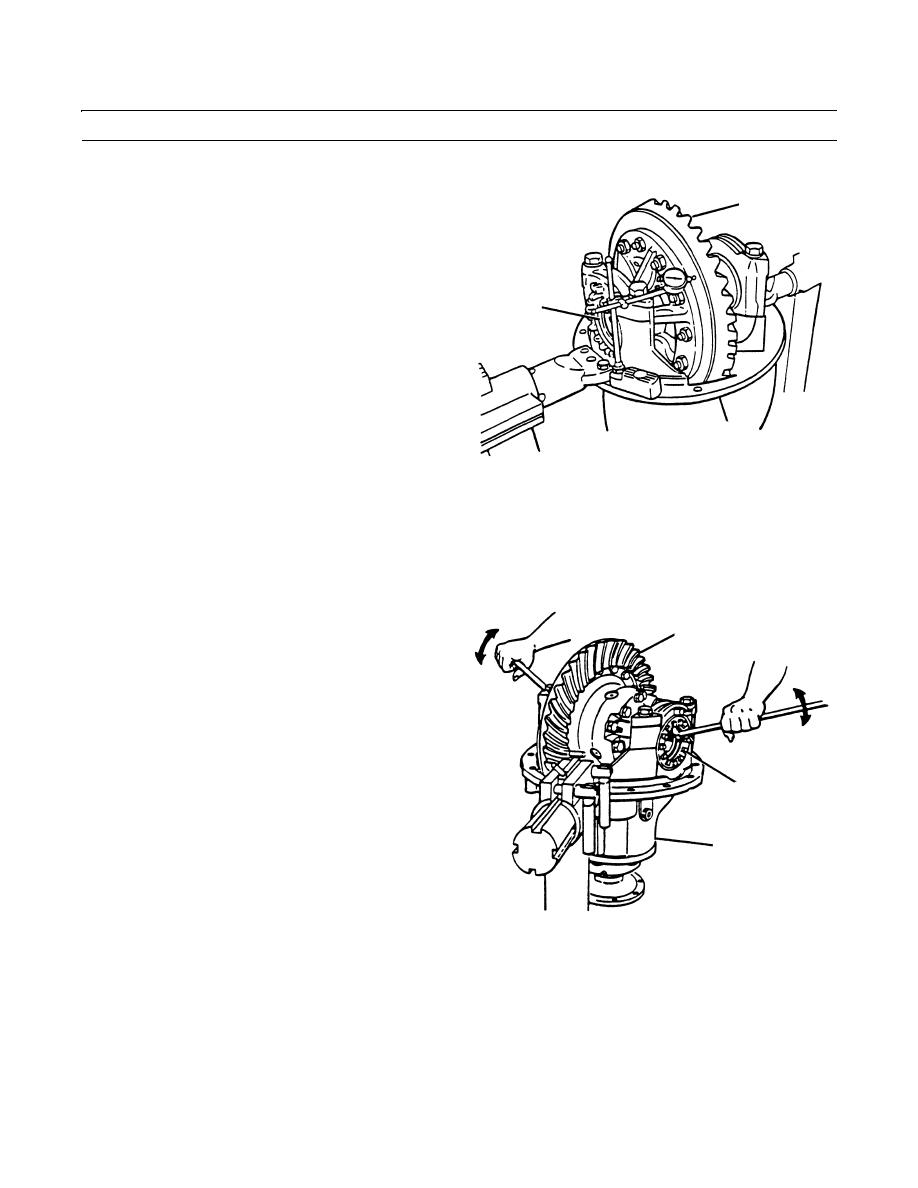

Attach a dial indicator on the mounting flange of the

13

differential carrier (8).

2.

Adjust the dial indicator so that the plunger is against

the back surface of the ring gear (13).

4

8

409-1253

CAUTION

When turning bearing adjusting rings, always use a tool that engages two or more opposite notches in the

ring. A large screwdriver can be used for this purpose. Failure to do so could cause damage to adjusting ring

lugs.

3.

Loosen the bearing adjustment ring (4) opposite ring

13

gear (13) so that a small amount of end play shows on

dial indicator. Move differential assembly and ring

gear (13) left and right with suitable pry bars while

reading dial indicator. Do not allow pry bars to touch

bearings (9 thru 11).

4.

Tighten bearing adjustment ring (4) opposite ring gear

(13) so that no end play shows on dial indicator. Move

the differential assembly and ring gear (13) left and

right as needed.

4

5.

Tighten each bearing adjusting ring (4) one notch from

zero end play.

8

6.

To check runout of ring gear (13), attach dial indicator

on mounting flange of differential carrier (8). Adjust

dial indicator so that plunger is against back surface of

ring gear (13).

409-1254

7.

Adjust dial of indicator to zero.

0296 00-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |