|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

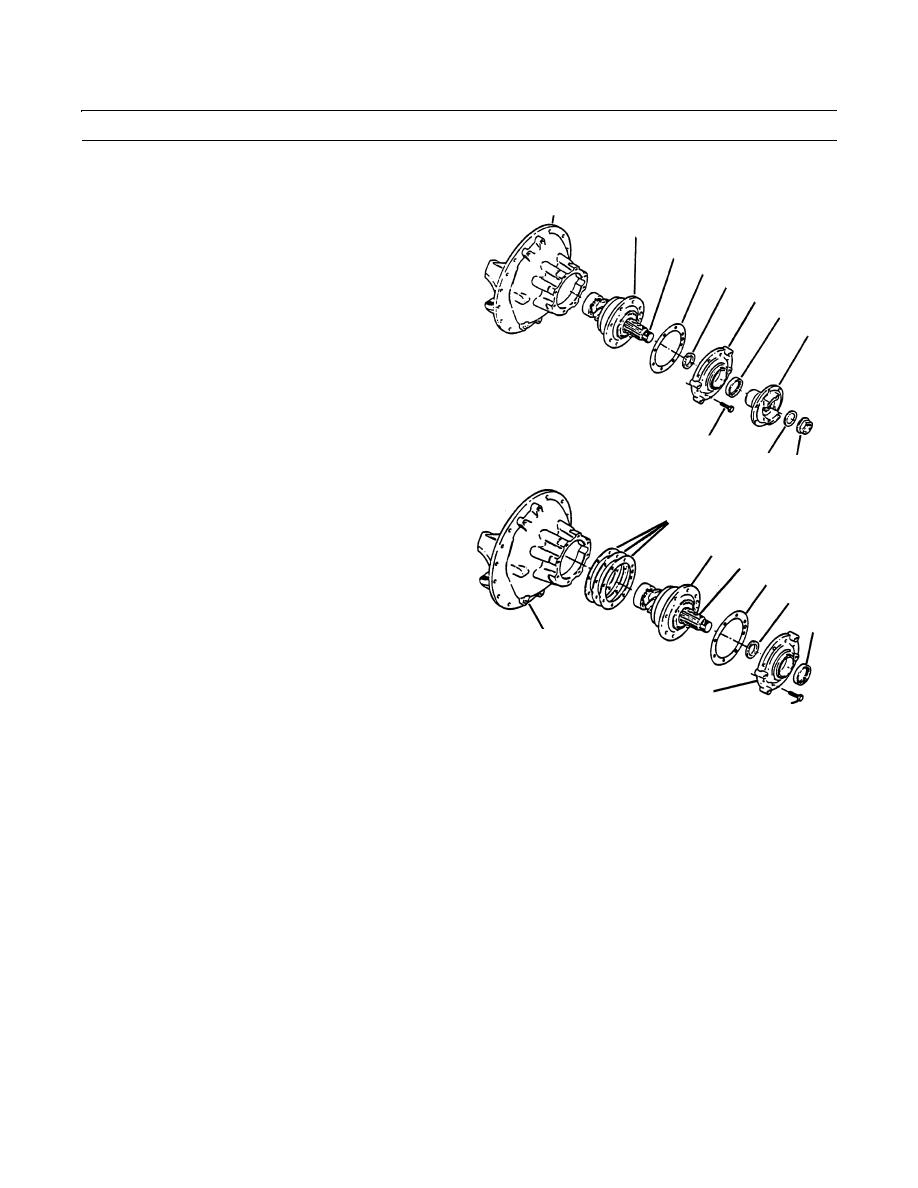

FRONT DIFFERENTIAL CARRIER ASSEMBLY MAINTENANCE - CONTINUED

0296 00

ASSEMBLY - CONTINUED

9.

Apply a thin film of clean lubricant to inner surface of

8

bevel pinion bearing oil seal (23).

20

19

10.

Apply a thin film of clean lubricant to seal bore in pin-

25

ion bearing cage cover (22).

24

22

11.

Use a press or suitable sleeve and mallet to install

23

bevel pinion bearing oil seal (23) into pinion bearing

34

cage cover (22).

12.

Use a feeler gauge to check gap between pinion bear-

ing oil seal (23) flange and pinion bearing cage cover

(22) at several points around the seal (23). Gap must

be within 0.015 to 0.030 in. (0.381 to 0.762 mm). The

difference between the largest and smallest gap mea-

21

surements must not exceed 0.010 in. (0.254 mm).

36

35

409-1243

13.

Temporarily install bevel pinion (19) and bearing cage

(20) assembly in differential carrier (8). Do not install

26

shims (26) under bearing cage (20).

20

14.

Install new gasket (25) on bearing cage (20).

19

25

15.

Install pinion bearing cage thrust washer (24), bearing

24

cage (20) and bearing cage cover (22), and secure with

23

eight capscrews (21). Hand tighten capscrews (21).

8

16.

To adjust bearings, install companion flange (34), nut

(35) and washer (36) on bevel pinion (19). Companion

flange (34) must be against outer bearing.

22

21

409-1241

17.

Fasten yoke nut tool to companion flange (34). Use

fabricated yoke nut tool to hold bevel pinion (19) in

position when nut (35) is tightened.

18.

Torque nut (35) on bevel pinion (9) to 300-400 lb-ft (407-542 Nm).

19.

Remove yoke nut tool from companion flange (34).

20.

Attach a torque wrench on bevel pinion nut (35). Rotate bevel pinion (19) and read value indicated on torque wrench.

New pinion bearings should be preloaded between 5 and 45 lb-in. (0.6 and 5.1 Nm) of torque. Reused pinion bearings

should be preloaded between 10 and 30 lb-in. (1.1 and 3.4 Nm).

NOTE

Do not read starting torque. Read only torque value after bevel pinion starts to rotate. Starting torque will

give a false reading.

21.

Increase bearing preload by removing bevel pinion (19) and bearing cage (20) assembly from differential carrier (8) and

installing a thinner bearing spacer (29). Repeat steps 14 thru 20.

22.

Decrease bearing preload by removing bevel pinion (19) and bearing cage (20) assembly from differential carrier (8)

and installing a thicker bearing spacer (29). Repeat steps 14 thru 20.

23.

Remove nut (35), washer (36) and companion flange (34) from bevel pinion (19).

0296 00-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |