|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

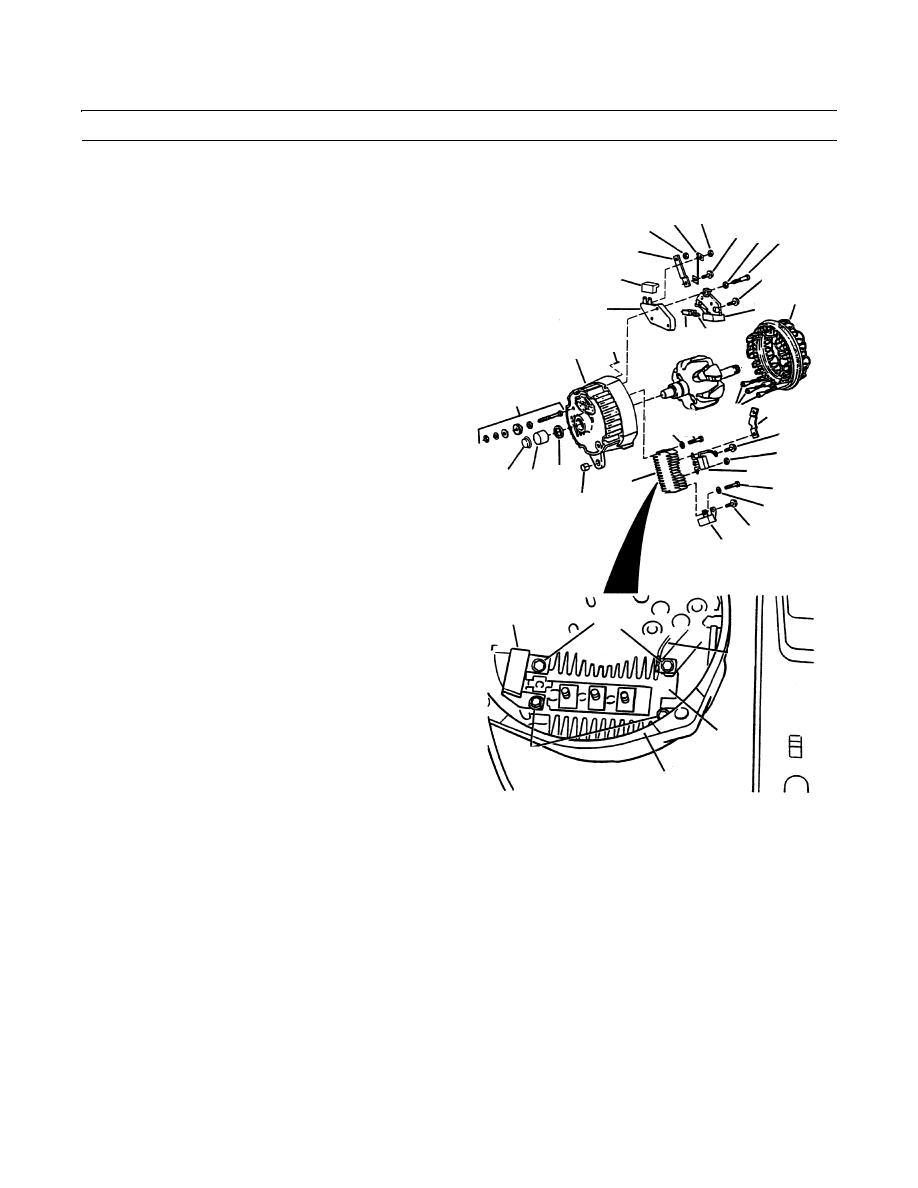

ALTERNATOR ASSEMBLY MAINTENANCE (152 HP) - CONTINUED

0284 00

DISASSEMBLY - CONTINUED

9.

Remove three nuts (16) that connect stator lead termi-

26 38

32

nal clips (17) to diode trio (18).

25 30 29

33

10.

Remove stator (8) from slip ring end frame (5).

19

11.

Remove insulated screw (19) securing diode trio (18)

27

8

to brush and holder assembly (20). Remove diode trio

28

20

(18).

20 31

43

NOTE

5

Screws and springwashers are located on

34,35,36

the rectifier bridge, closest to outside of

37

17

frame. One of the screws secures the lower

22 21

19

contact of capacitor.

16

12.

Remove two screws (21) and two springwashers (22)

18

40 39 41

from rectifier bridge (23). Discard springwashers.

23

21

42

22

NOTE

25

Screw and lockwasher assemblies are

24

located on the rectifier bridge, closest to

center of frame. One assembly secures the

upper contact of capacitor. The other

24

assembly secures wire lead.

25

13.

Remove two screw and lockwasher assemblies (25)

26

from rectifier bridge (23). Remove capacitor (24) and

rectifier bridge (23) from frame (5). Discard screw and

lockwasher assemblies.

14.

Remove rubber cover (27) from terminals of regulator

23

(28).

21,22

15.

Remove insulated screw (19), screw (29) and lock-

5

washer (30), securing brush and holder assembly (20),

brush springs (31) and regulator (28). Discard lock-

409-1098

washer. Remove parts (20, 28 and 31) from frame (5).

16.

If necessary, remove nut (32), connector (33) and battery terminal assembly parts (34).

17.

If necessary, remove relay terminal cap (35), relay terminal assembly parts (36) and connector (37).

18.

If necessary, remove nut (38) and wire lead (26) from regulator (28).

NOTE

If roller bearing is not being removed, apply pressure sensitive tape over it for protection against dirt. Do not

use friction tape or other tape that will leave a residue behind.

19.

If necessary for replacement, push roller bearing (39) out of frame (5) and remove seal (41) and plug (40). Discard seal.

20.

If necessary, remove bushing (42) and pin (43) from frame (5).

0284 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |