|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

CRANKSHAFT MAIN BEARINGS MAINTENANCE - CONTINUED

0272 00

INSTALLATION - CONTINUED

56.

Check bearing clearance using steps 15 thru 20.

57.

Install no. 1 main bearing, steps 22 thru 26.

CAUTION

Be very careful not to scratch the crank-

shaft or the bearing bore during the instal-

lation of the upper bearing half. A

scratched or damaged crankshaft, or bear-

ing bore, could result in premature engine

failure.

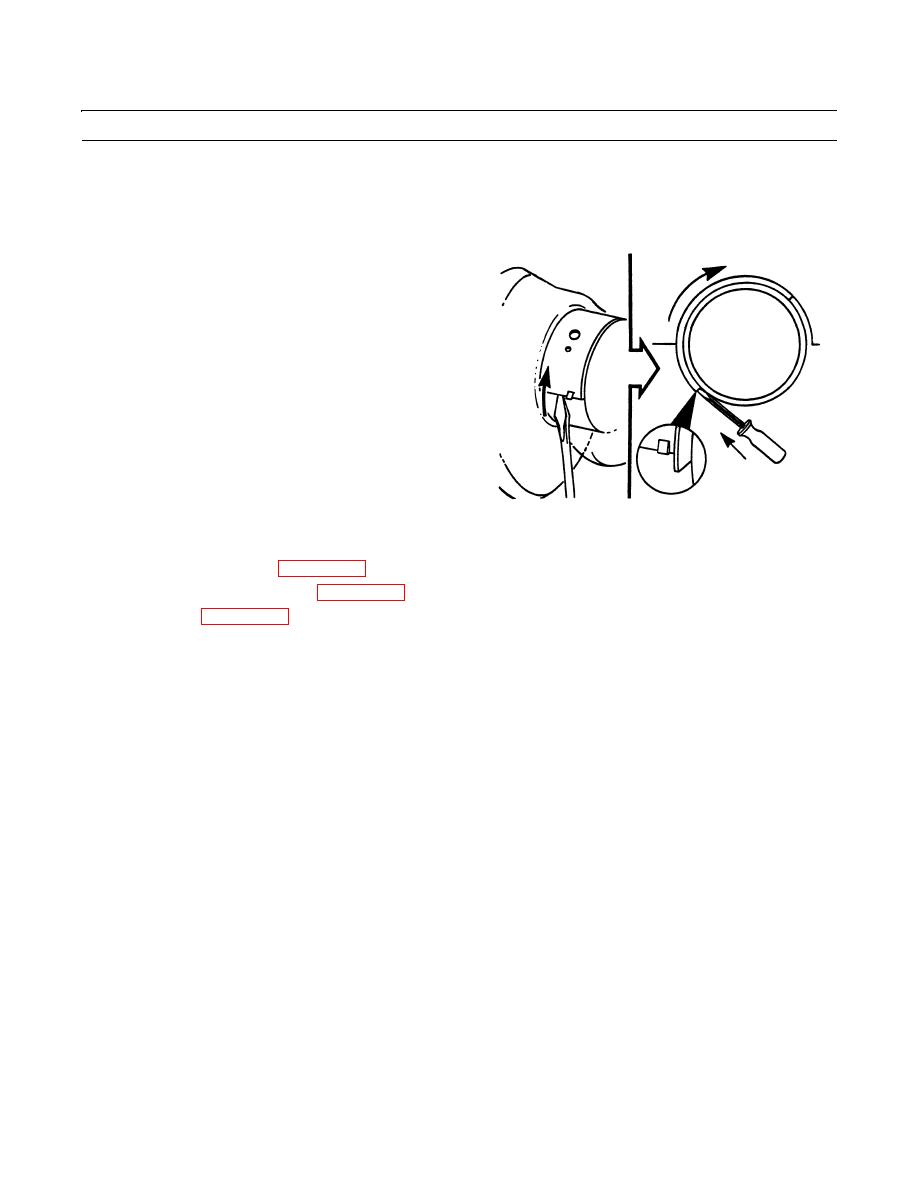

58.

To insert upper half of no. 1 main bearing into bearing

bore, simultaneously push the upper bearing half with

a flat blade screwdriver and turn the crankshaft until

bearing tab is in notch in cylinder block.

409-4112

59.

Continue with no. 1 bearing installation, steps 31 and

34 thru 36.

60.

Crankshaft must turn freely. If it does not turn with relative ease, check bearing installations and size of bearings.

61.

Check crankshaft end play (WP 0271 00).

62.

Install engine oil pump inlet tube (WP 0220 00).

63.

Install oil pan (WP 0219 00).

END OF WORK PACKAGE

0272 00-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |