|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

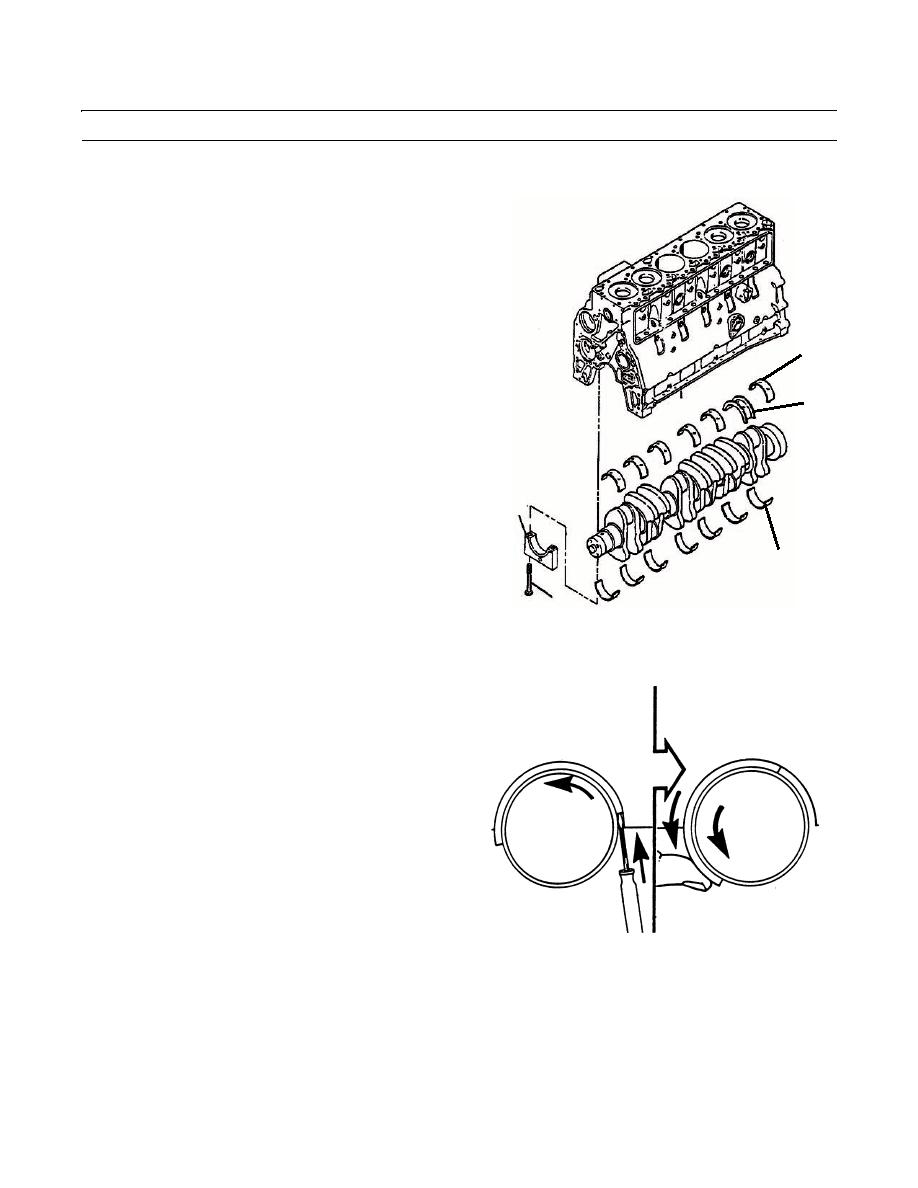

CRANKSHAFT MAIN BEARINGS MAINTENANCE - CONTINUED

0272 00

INSTALLATION - CONTINUED

37.

If main bearing position number on bearing cap is

missing or hard to read, etch the correct number on the

bearing cap so that it is facing the oil cooler side of the

engine.

38.

Remove two capscrews (1) and bearing cap (2) from

no. 1 main bearing. Remove lower bearing half (11)

from bearing cap (9).

CAUTION

3

Be very careful not to scratch the crank-

shaft or the bearing bore during the

5

removal of the upper bearing halves. A

scratched or damaged crankshaft, or bear-

ing bore could result in premature engine

failure.

39.

Use a flat blade screwdriver to remove the upper half

2

of main bearing (3) at position no. 1 because the

crankshaft journal for no. 1 main bearing does not

have an oil hole.

4

1

409-1930

40.

Gently push end of upper bearing half to loosen it

from the cylinder block.

41.

Press finger against bearing and turn crankshaft to roll

the bearing from the cylinder block.

409-4111

CAUTION

If crankshaft is turned in the wrong direction, the tab on the upper bearing half will be pushed between the

crankshaft and main bearing bore in the block. This could cause damage to the block and the crankshaft.

42.

Remove no. 7 main bearing by using removal steps 4 thru 8.

0272 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |