|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

CRANKSHAFT MAIN BEARINGS MAINTENANCE - CONTINUED

0272 00

INSTALLATION - CONTINUED

4.

Insert bearing removal/installation tool, into bearing journal oil hole so that it will push against tab end of bearing.

CAUTION

If the crankshaft is turned in the wrong direction, the bearing tab will be pushed between the crankshaft and

bearing area in the block. This could cause damage to the block and the crankshaft.

5.

Slowly turn crankshaft in the correct direction until upper bearing tab is in the cylinder block notch.

6.

Remove bearing removal/installation tool from crankshaft oil hole.

NOTE

After each upper bearing half is installed, install the respective lower bearing half and bearing cap as

described in the following steps.

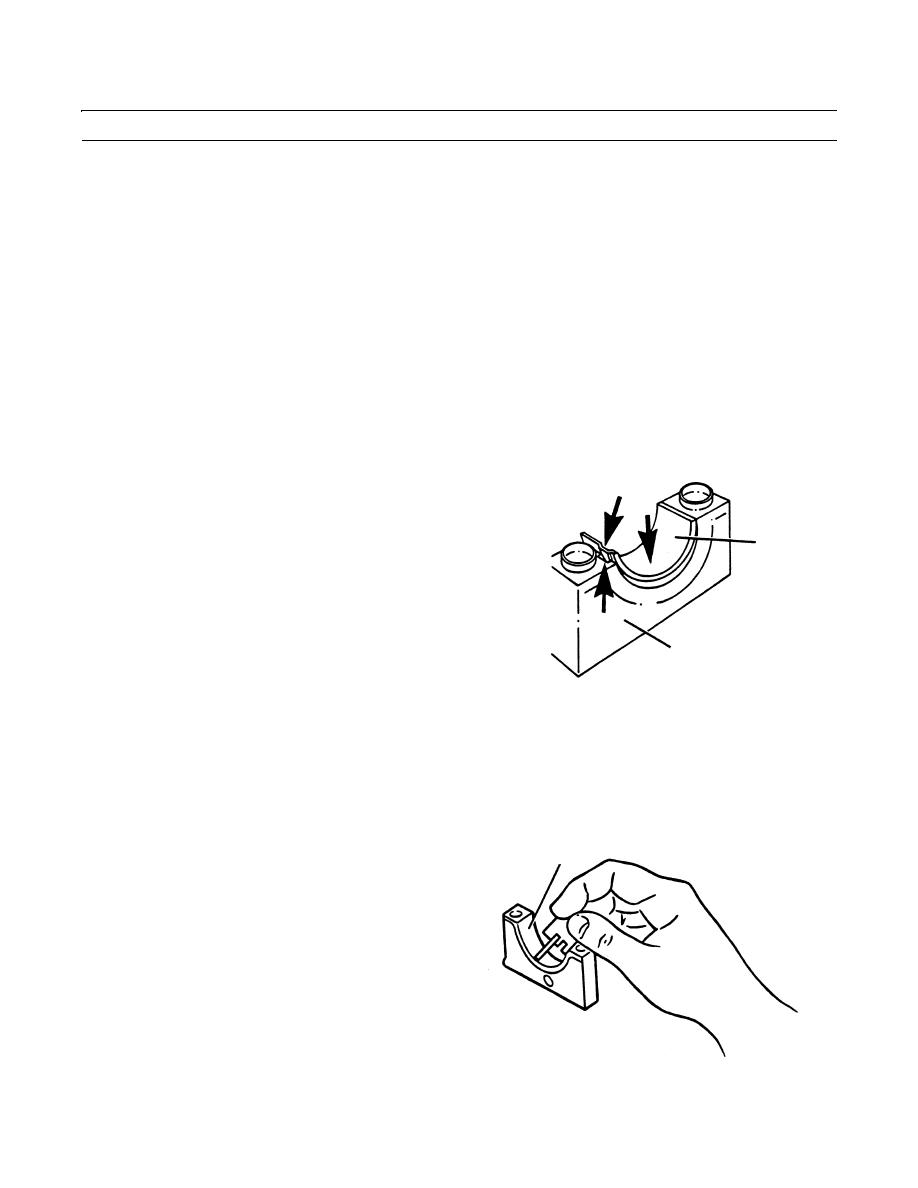

7.

Install a new dry lower main bearing half (4) in bear-

ing cap (2). Tab on bearing must be in the notch in

bearing cap. If used main bearing is being installed,

install bearing in the same bearing cap it was removed

4

from.

9

409-932

NOTE

Do not turn crankshaft after plastigage is in position. Plastigage will be distorted.

8.

Place plastigage on the surface of new lower main

4

bearing half (4).

409-912

0272 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |