|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

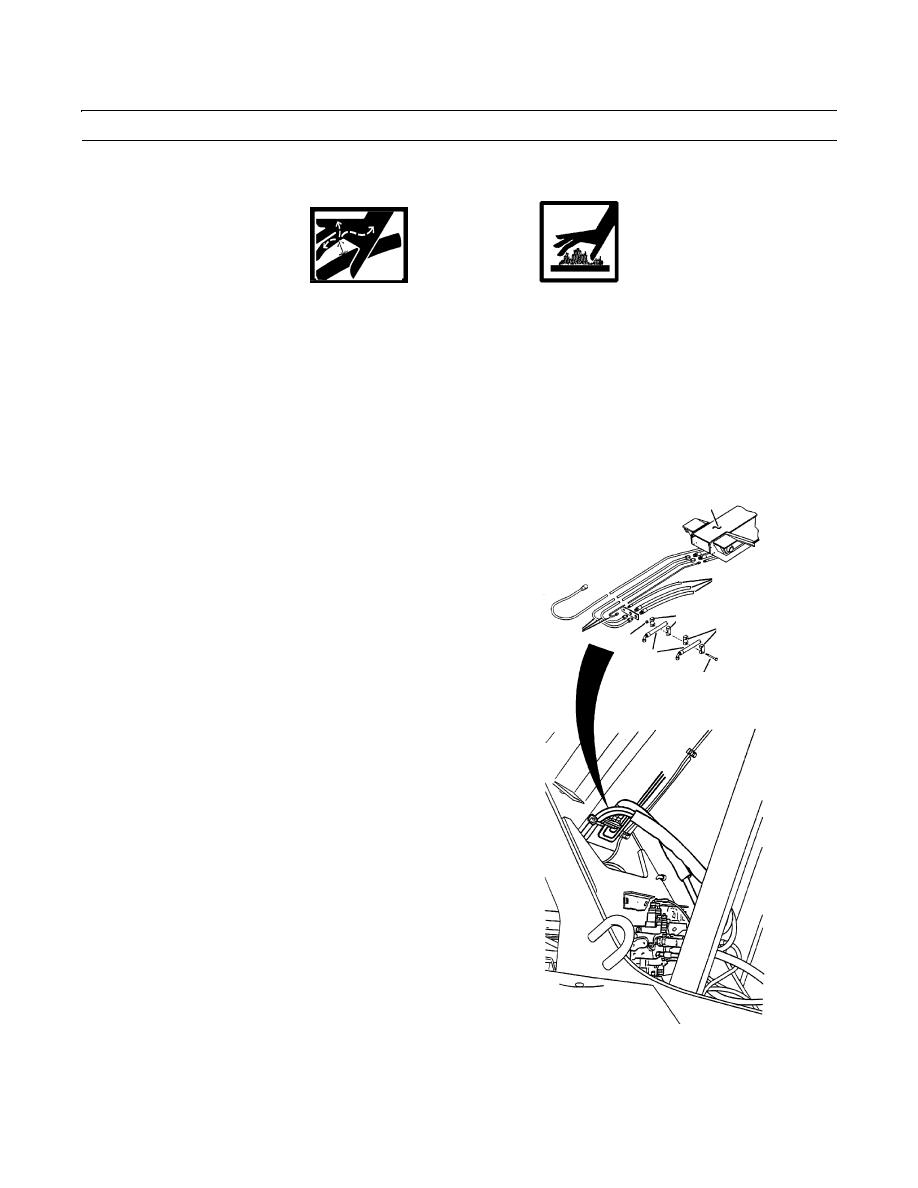

OUTER BOOM MAINTENANCE - CONTINUED

0264 00

REMOVAL

WARNING

Do NOT remove hydraulic tank filler cap or disconnect or remove any hydraulic system line or fitting

unless hydraulic system pressure has been relieved. Hydraulic system pressure can be over 3000 psi

(20685 kPa), even with engine and pump OFF. To relieve pressure, lower all hydraulic attachments to

the ground and shut down engine. Move control levers through all operating positions, then SLOWLY

loosen hydraulic tank filler cap. After maintenance, tighten all connections before applying pressure.

Escaping hydraulic fluid under pressure can penetrate the skin, causing injury or death.

Before performing step 2, make sure lines and extend cylinder hoses under boom are closed securely

using metal plugs. Hydraulic oil under pressure can spray from hoses and lines causing bodily injury if

lines and hoses are not closed securely.

CAUTION

3

Wipe the area clean around all hydraulic

connections to be opened during removal

and disassembly. Cap oil lines and plug

1

holes after removing lines. Contamination

of the hydraulic system could result in pre-

6

6

mature failure.

4

7

2

NOTE

5

If more than one hydraulic line is to be

removed, tag lines to assure proper instal-

lation. Use suitable container to catch any

hydraulic oil that may drain from system.

1.

Start engine and raise outer boom (3) as necessary to

access hoses (1 and 2). Stop engine (TM 10-3930-660-

10).

WARNING

Disconnect hoses carefully during step 3.

Hydraulic oil may be under pressure. Fail-

ure to follow this precaution will cause

personal injury.

2.

Tag and disconnect three hoses (1) from lines (4) at

bulkhead. Plug three hoses (1) with metal caps.

409-1427

3.

Remove capscrew (5), four clamp halves (6) and nut

(7) securing two hoses (2). Leave hoses (2) plugged

with metal caps.

0264 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |