|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-2

INTERMEDIATE BOOM MAINTENANCE - CONTINUED

0263 00

INSTALLATION - CONTINUED

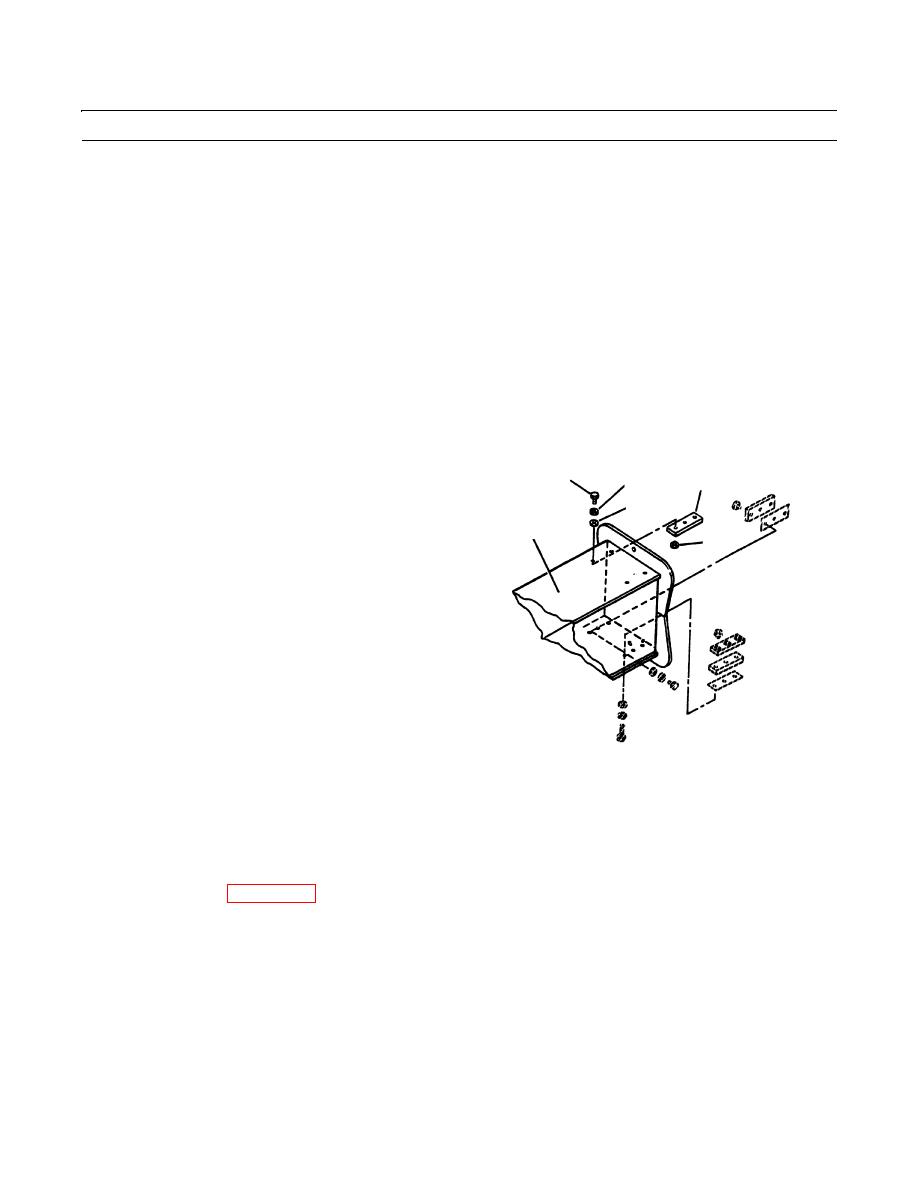

4.

Position shims (17 and 18), spacers plates (16), wear pads (15) and wear pad inserts (19) between intermediate boom (1)

and outer boom (2). Chamfered side of wear pad (15) must be facing towards intermediate boom (1). Widest portion of

wear pad (15) must be facing towards outside of outer boom (2).

5.

Apply loctite to capscrews (20). Secure wear pad assemblies, parts (15 thru 19) to outer boom (2) with flatwashers (22),

new lockwashers (21) and capscrews (20). Torque capscrews (20) to 30 lb-ft (40 Nm).

NOTE

Shims are used as required. Install same quantity of shims as noted during removal.

6.

Position wear pads (8), shims (9 and 10) and wear pad inserts (11), between outer boom (2) and intermediate boom (1).

Chamfered side of wear pad (8) must be facing towards intermediate boom (1). Widest portion of wear pad (8) must be

facing towards bottom of outer boom (2).

7.

Apply loctite to capscrews (12). Secure wear pad assemblies, parts (8 thru 11) to outer boom (2) with flatwashers (14),

new lockwashers (13) and capscrews (12). Torque capscrews (12) to 30 lb-ft (40 Nm).

8.

Position wear pads (3) and wear pad inserts (4)

5

6

3

between outer boom (2) and intermediate boom (1).

7

Chamfered side of wear pad (3) must be facing

towards intermediate boom (1). Widest portion of

2

4

wear pad (3) must be facing towards outside of outer

boom (2).

9.

Apply loctite to capscrews (5). Secure wear pad

assemblies, parts (3 and 4) with flatwashers (7), new

lockwashers (6) and capscrews (5). Torque capscrews

(5) to 30 lb-ft (40 Nm).

409-1424

10.

Using hoist and sling to move inner boom, check for clearance of 0.01 to 0.13 in. (0.25 to 3.30 mm) between intermedi-

ate boom surface and wear pads. If necessary, add or subtract shims (9, 10, 17 and 18) until clearance is within specifi-

cations.

11.

Use hoist to slide intermediate boom (1) in until it is approximately 1 ft (0.3 m) from end of outer boom (2).

12.

Install wood block between outer boom (2) and intermediate boom (1) for use during installation of inner boom.

13.

Install inner boom (WP 0263 00).

14.

Remove wood block.

15.

Operate boom and check for proper operation (TM 10-3930-660-10).

END OF WORK PACKAGE

0263 00-5/(-6 Blank)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |