|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-660-24-1

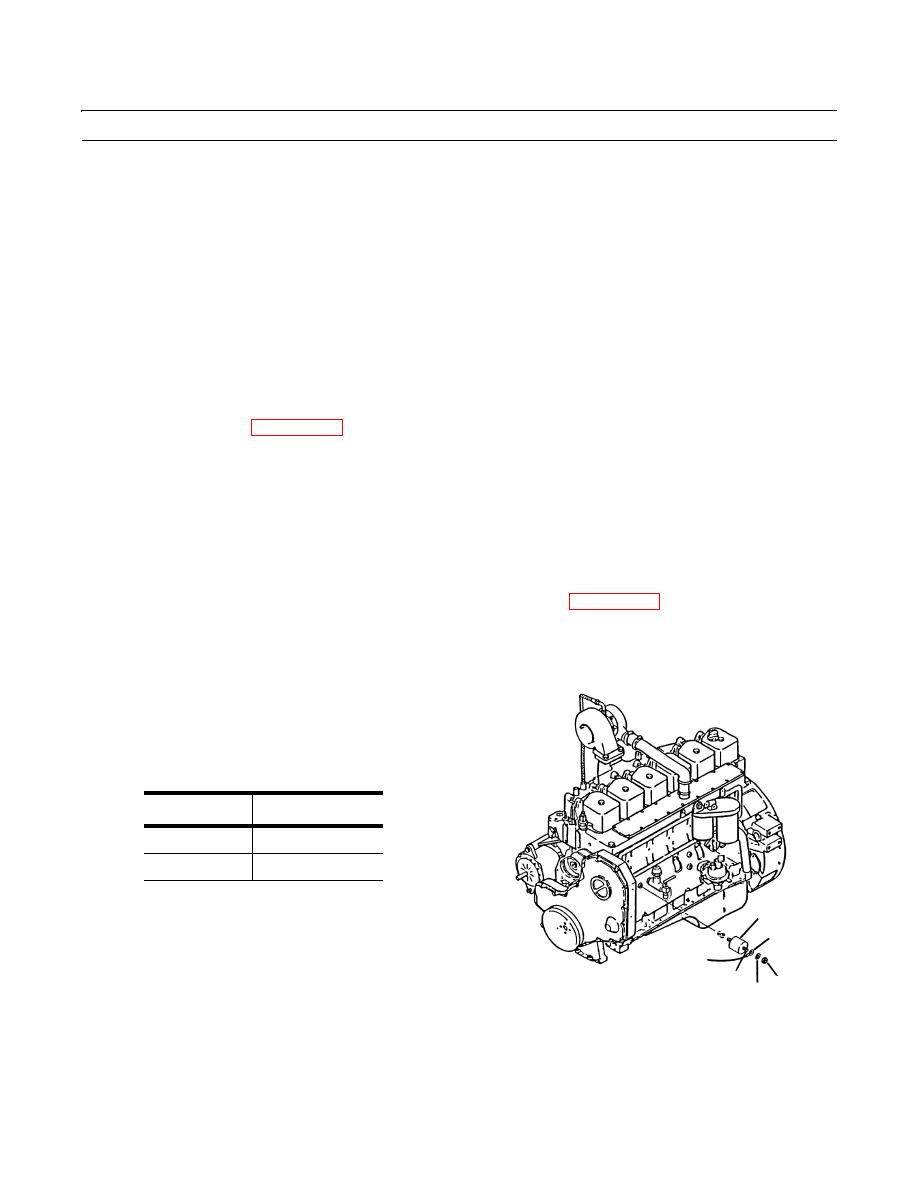

ENGINE OIL PRESSURE SENDER MAINTENANCE - CONTINUED

0099 00

INSTALLATION - CONTINUED

NOTE

Perform steps 4 through 6 for the 152 hp engine.

4.

Apply loctite to threads of fitting (5) and install fitting into engine (6).

5.

Apply loctite to threads of sender (4).

6.

Install sender (4) into fitting (5).

NOTE

Perform step 7 for both engines.

7.

Connect electrical lead (3) with new lockwasher (2) and nut (1).

8.

Connect battery cables (WP 0107 00).

TESTING

1.

Remove nut (1) and lockwasher (2) to disconnect electrical lead (3) at sender (4). Discard lockwasher.

NOTE

Do not remove sender from engine.

2.

Connect one ohmmeter lead to the sender terminal (A) and the other lead to the engine ground.

3.

Use STE/ICE-R to monitor engine oil pressure. See STE/ICE-R procedures (WP 0008 00).

4.

Start the engine and observe both the STE/ICE-R oil pressure readout and the ohmmeter. The pressure sender (4) should

have the following resistance readings.

NOTE

The 0 psi reading should be done at a

decreasing pressure. The 40 psi reading

should be read on an increasing pressure.

Oil Pressure

Resistance

0 psi

227-257 ohms

40 psi

92-114 ohms

5.

Replace sender (4) if resistance requirements are not

4

met. See Installation.

3

6.

Connect electrical lead (3) at sender (4). Install new

lockwasher (2) and nut (1).

A

1

2

409-367

END OF WORK PACKAGE

0099 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |