| |

TM10-3930-660-20

18-32.

BOOM HOIST CYLINDERS - REPLACE (Cont'd)

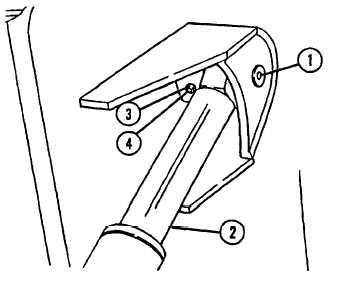

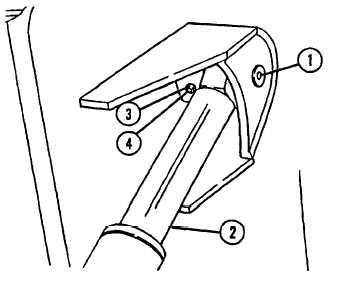

Apply anti-seize compound to lower pivot

pin (7) as installed.

2.

ALIGN CYLINDER BASE LOWER MOUNTING

HOLES AND INSTALL LOWER PIVOT PIN

(7), SCREW (9) AND NEW LOCKNUT (8).

3.

CONNECT HYDRAULIC LINES (5 AND 6) AS

TAGGED DURING CYLINDER (2) REMOVAL.

4.

CAREFULLY RAISE CYLINDER

LIFTING DEVICE UNTIL ROD

CYLINDER (2) IS AIMED AT

MOUNTING HOLE ON BOOM.

(2) USING

EYE OF

PIVOT PIN

Have assistant signal operator

eye of cylinder (2) is aligned

pivot pin hole.

when rod

with boom

If installing both cylinders (2) at the

same time, note that in step 5 one

cylinder will extend, and the other will

remain stationary.

Cylinder (2) that extended must be

aligned and then secured to boom with

pivot pin (1).

When cylinder (2) that extended is

secured to boom, other cylinder (2) will

respond to controls, and can be extended

as

5.

6.

7.

well.

START ENGINE AND RUN AT FULL

THROTTLE, TM10-3930-660-10.

EXTEND CYLINDER ROD UNTIL UPPER PIVOT

PIN (1) CAN BE INSTALLED.

REPOSITION

CYLINDER (2), AS NECESSARY, USING

LIFTING DEVICE.

STOP ENGINE, TM10-3930-660-10.

Apply anti-seize compound to upper pivot

pin (1) as installed.

18-130

8.

9.

10.

11.

INSTALL UPPER PIVOT PIN (1), SCREW (4)

AND NEW LOCKNUT (3).

DISCONNECT LIFTING DEVICE FROM

CYLINDER (2) AND BOOM. REMOVE

BOARD FROM ACROSS VEHICLE DECK.

BLEED AIR FROM HYDRAULIC SYSTEM.

a.

b.

c.

Start engine, TM10-3930-660-10.

Operate boom hoist functions.

Raise and lower boom five times.

Stop engine and relieve hydraulic

pressure by operating boom hoist

functions of hydraulic joystick,

TM10-3930-660-10.

INSTALL TRANSMISSION COVER,

PARA. 16-6.

|