| |

TM10-3930-660-20

18-16.

MLRS ATTACHMENT CYLINDER - REPLACE (Cont‘d)

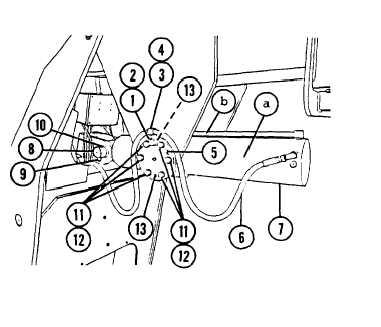

2. INSTALL TWO BEARING

ATTACHMENT CYLINDER

CAPS (5) AND MLRS

(7).

Install bearing caps (5) so that jack

bolt holes (13) are positioned as-shown.

Position cylinder (7) with the rod end

oil feed tube (b) up.

a. Apply Loctite 242 to six bolts

(11) .

b. Install six bolts (11) and six new

lockwashers (12).

c. Repeat steps a-b for other

bearing cap (5).

3. SUPPORT REAR PORTION OF MLRS

ATTACHMENT CYLINDER (7) USING A HOIST

AND SLING OR OTHER SUITABLE LIFTING

DEVICE.

Failure to support rear portion (a) of

MLRS attachment cylinder (7) when

installing pivot pin (8) may cause

personal injury and damage to cylinder

(7).

Apply anti-seize compound to pivot pin

(8).

4. INSTALL PIVOT PIN (8).

a. Secure pivot pin (8) with bolt (10)

and new locknut (9).

b. Raise or lower MLRS attachment

cylinder (7) as needed to ease

pivot pin (8) installation.

5. INSTALL TWO HYDRAULIC LINES (6). USE

TAGS TO IDENTIFY CONNECTIONS.

6. INSTALL NEW LOCKWASHER (4), CLAMP (3),

NEW LOCKWASHER (2) AND CAPSCREW (1) TO

EACH OF THE TWO BEARING CAPS (5).

Position hydraulic lines (6) in clamps

(3) so cylinder (6) can fully extend.

7. CYCLE MLRS ATTACHMENT CYLINDER (7)

FIVE TIMES TO BLEED ANY AIR IN

HYDRAULIC SYSTEM, TM10-3930-660-10.

Excessive air in hydraulic system may

temporarily prevent cylinder (7) from

operating. Attempt to cycle cylinder

(7) as required until its operation is

smooth and it fully extends and

retracts.

18-66

|