| |

TM10-3930-660-20

18-6.

MAIN CONTROL VALVE ASSEMBLY - ADJUST/REPLACE (Cont’d)

ADJUSTMENT - BOOM LOWER RELIEF VALVE

The main relief valve pressure must be

adjusted above normal operating pressure

to permit the boom lower relief valve

pressure to be adjusted.

Main relief valve pressure is then

returned to normal operating pressure at

the end of this procedure.

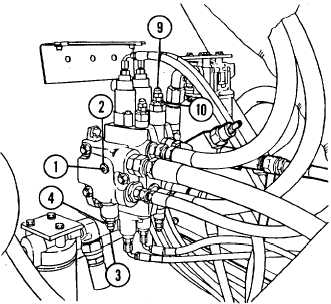

1. CONNECT PRESSURE GAUGE TO VALVE PORT.

a.

b.

c*

d.

Remove main relief valve plug

assembly (1).

Connect O to 5000 psi pressure

gauge to plug assembly port (2).

Remove acorn nut (3) covering

slotted head adjusting screw.

While holding adjusting screw,

loosen and back off jam nut (4)

which secures adjusting screw.

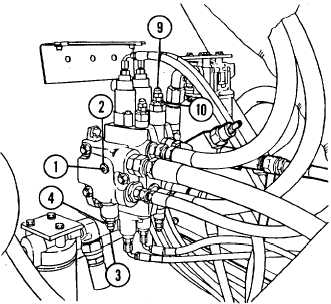

3. ADJUST BOOM LOWERING RELIEF VALVE

2. ADJUST MAIN RELIEF VALVE PRESSURE TO

3,100 psi.

Engine may be operated at idle or full

throttle when performing pressure tests.

a.

b.

c.

d.

Start engine, TM10-3930-660-10.

Operate boom extend, retract,

hoist or lower function until

hydraulic oil is passing over

relief valve.

Continue to hold

hydraulic lever in that position

so oil passes over relief valve

during relief valve adjustment.

Turn adjusting screw clockwise

(in) until pressure on gauge reads

3,100 psi.

Release hydraulic function lever.

PRESSURE BETWEEN 1000 AND 1100 psi.

a.

b.

c.

d.

e.

Remove acorn nut (9) covering

slotted head adjusting screw.

While holding adjusting screw,

loosen and back off jam nut (10)

which secures adjusting screw.

Operate boom lower function

until boom is fully lowered.

Continue to hold boom control

lever in position so hydraulic oil

passes over relief valve.

Read relief valve pressure on

pressure gauge.

To increase relief pressure, turn

adjusting screw clockwise (in).

To decrease pressure, turn

adjusting screw counterclockwise

(out) .

18-27

|