| |

TM10-3930-660-20

18-6.

MAIN CONTROL VALVE ASSEMBLY -

ADJUST/REPLACE (Cont’d)

C.

d.

e.

f.

g.

h.

Operate boom extend function until

boom is fully extended. Continue

to hold boom control lever in

extend position so hydraulic oil

passes over relief valve.

Read relief valve pressure on

pressure gauge.

To increase relief pressure, turn

adjusting screw clockwise (in).

To decrease pressure, turn

adjusting screw counterclockwise

(out).

When desired relief pressure is

obtained, release boom extend

lever.

Hold adjusting screw in

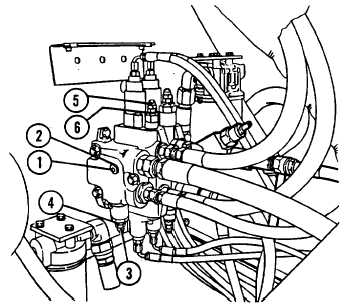

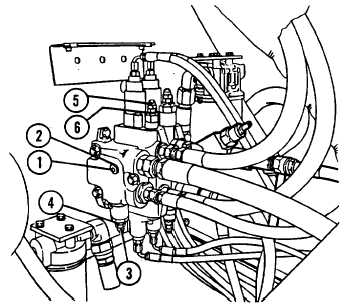

position and tighten jam nut (6).

Install acorn nut (5).

4. ADJUST MAIN RELIEF VALVE

BETWEEN 2,750 AND 2,850 psi

a.

b.

c.

d.

Operate boom extend, retract,

hoist or lower function until

hydraulic oil is passing over

relief valve. Continue to hold

hydraulic lever in that position

so oil passes over relief valve

during relief valve adjustment.

Turn main relief valve adjusting

screw counterclockwise (out) until

pressure on gauge reads between

2,750 and 2,850 psi.

Release hydraulic function lever.

Hold adjusting screw in position

and tighten jam nut (4). Install

acorn nut (3).

5. STOP ENGINE, TM10-3930-660-10.

WARNING

Hydraulic oil in the system can be under

pressures over 3000 psi with the engine

OFF. ALWAYS relieve pressure in

hydraulic lines before attempting to

remove any component in the hydraulic

system. With engine OFF, starter switch

in RUN position, and MLRS attachment on

the ground, move control levers through

all operating positions several times to

relieve line pressure. Relieve pressure

in hydraulic oil tank by loosening

filler cap very slowly. Failure to

follow these precautions could result

i

n

6.

serious personal injury.

REMOVE PRESSURE GAUGE.

Unscrew pressure gauge from main

relief valve plug assembly port (2).

18-23

|