| |

TM10-3930-660-20

18-4. TANDEM GEAR PUMP -

TEST/REPLACE (Cont’d)

CAUTION

Tandem gear pump must be purged of air

before engine is started. Refer to

para. 18-3 for purging instructions.

Failure to purge air as directed may

result in severe damage to tandem gear

pump.

3. PURGE AIR FROM THE TANDEM GEAR PUMP,

PARA. 18-3.

4. INSTALL TRANSMISSION ACCESS COVER,

PARA. 16-6.

TESTING

NOTE

Both the large pump section and the

small pump section of the tandem gear

pump are tested in the same manner.

1.

2.

3.

4.

5.

REMOVE TRANSMISSION COVER,

PARA. 16-6.

PREPARE AND SET UP THE IN-LINE

FLOWMETER FOR TESTING.

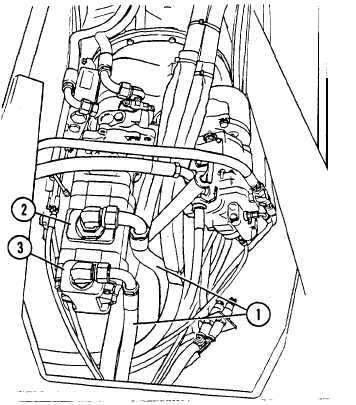

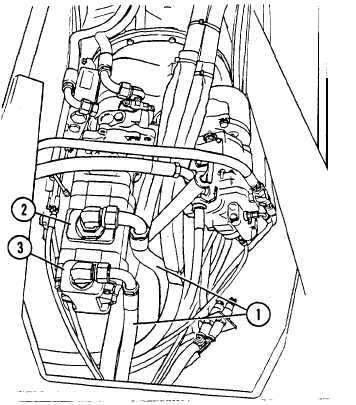

DISCONNECT PUMP OUTLET HOSE (1) FROM

THE PUMP SECTION BEING TESTED.

CONNECT A TEST HOSE FROM THE OUTLET

SIDE OF THE SECTION BEING TESTED TO

THE INLET PORT OF THE FLOWMETER.

CONNECT THE HYDRAULIC HOSE (1)

REMOVED IN STEP 3. TO THE OUTLET

PORT OF THE FLOWMETER.

Use the STE/ICE kit to monitor engine

speed. The hydraulic pumps are tested

at

6.

7.

specific engine rpms.

START THE ENGINE, TM10-3930-660-10.

IF THE LARGE PUMP SECTION (2) IS

BEING TESTED, ADJUST THE ENGINE

SPEED TO 2400 RPM, ADJUST PRESSURE

TO 2500 PSI, AND READ THE FLOW IN

GPM .

18-9

|