| |

TM 10-3930-659-34

5-17.

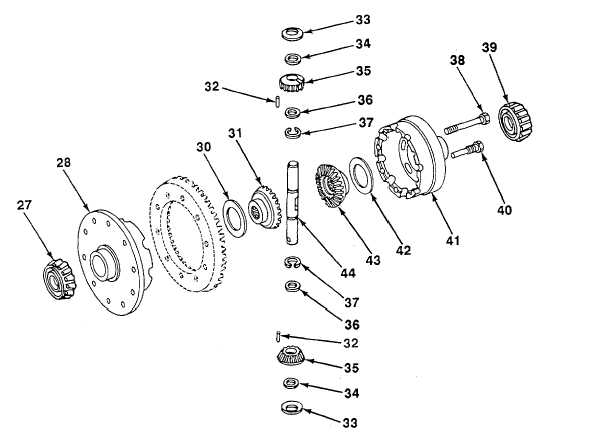

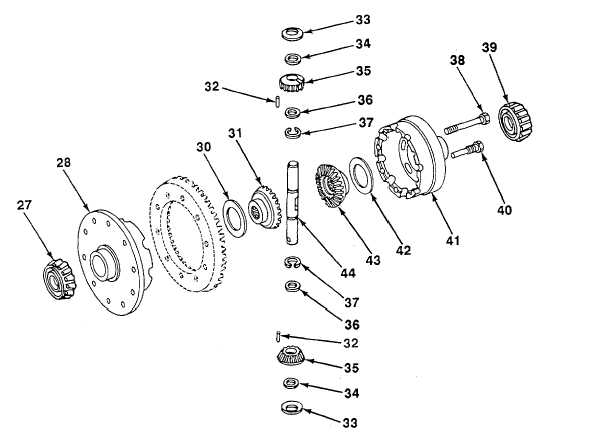

DIFFERENTIAL ASSEMBLY MAINTENANCE (Con’t).

4.

Heat two bearing cones (27 and 39) to a maximum of 300°F (1490C) in accordance with TM 9-214.

5.

Install bearing cone (27) on housing (28) until tight against housing.

6.

Install bearing cone (39) on cover (41) until tight against cover.

7.

Install 26 needle bearings (32) in two pinions (35). Apply petrolatum to needle bearings.

8.

Install two retaining rings (37), two thrustwashers (36), pinions (35), and four thrustwashers (33 and 34) on shaft

(44).

9.

Install thrustwasher (30) and bevel gear (31) on housing (28).

10.

Position shaft (44) in housing (28).

11.

Install thrustwasher (42) and bevel gear (43) in cover (41).

12.

Install cover (41) on housing (28) with eight screws (38) and short screw (40). Torque screws to 37 lb.-ft. (50 N•m).

Turn screws an additional one-quarter turn clockwise.

TA708380

5-170

|