| |

TM 10-3930-659-34

5-17.

DIFFERENTIAL ASSEMBLY MAINTENANCE (Con’t).

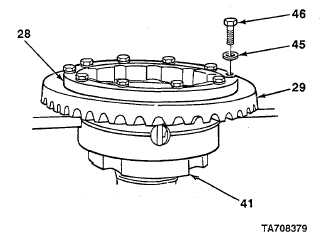

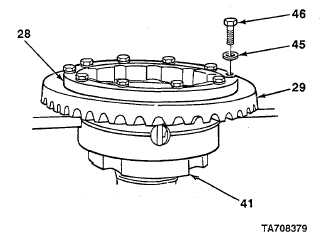

16.

Remove ten screws (46), washers (45), and ring gear (29) from housing (28).

17.

Remove four screws (38) and cover (41) from housing (28).

c.

CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective goggles and gloves, and

use only in a well-ventilated area. Avoid contact with skin, eyes, and clothes, and DO NOT breathe vapors.

DO NOT use near open flame or excessive heat. The solvent's flash point is 100°F-138°F (38°C-590C). If

you become dizzy while using cleaning solvent, immediately get fresh air and medical help. If solvent

contacts eyes, immediately wash your eyes and get medical aid.

1.

Clean metal parts with dry cleaning solvent and dry with a clean rag.

2.

Clean and inspect bearings in accordance with TM 9-214.

NOTE

Pinion shaft and ring gear are a matched set. If ring gear is damaged, pinion shaft MUST also be replaced

(see paragraph 5-15 or 5-16).

3.

Inspect ring gear for burrs, chips, and missing teeth. Replace damaged ring gear and pinion shaft.

4.

Inspect bevel gears and pinions for burrs, chips, and missing teeth. Replace damaged bevel gears orpinions.

5.

Inspect shaft for cracks, bends, and distortion. Replace damaged shaft.

6.

Inspect thrustwashers for distortion and excessive wear. Replace damaged thrustwashers.

7.

Inspect housing and cover for cracks, dents, and damage. Replace damaged housing or cover.

d.

ASSEMBLY

1.

Apply sealing compound (Item 15, Appendix B)

to threads of ten screws (46).

2.

Heat ring gear (29) to a maximum of 300°F

(149°C) in accordance with TM 9-214.

3.

Install ring gear (29) on housing (28) with ten

washers (45) and screws (46). Tighten screws in

a crisscross pattern, repeating tightening pattern

three times. Torque screws to 110 lb.-ft. (149

N•m).

5-169

|