| |

TM 10-3930-659-34

5-8.

TURBOCHARGER TEST AND REPAIR (Con’t).

CAUTION

DO NOT spray dry cleaning solvent directly into compressor or turbine housing. Direct spray may

damage parts.

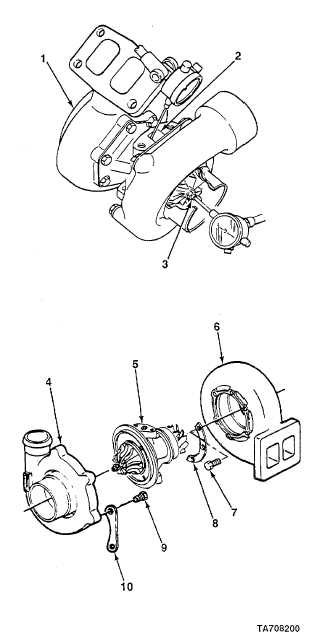

1.

Clean exterior of turbocharger (1) with dry

cleaning

solvent.

Dry

thoroughly

with

compressed air.

2.

Using dial indicator set, position indicator tip

through center housing oil return (2) until it

contacts wheel and shaft assembly (3). Zero

dial indicator.

3.

Hold wheel and shaft assembly (3) at both ends,

and move up and down with equal pressure.

Ensure that rotation is in same direction as dial

indicator tip travels. Maximum allowable bearing

clearance is 0.006 in. (0.152 mm).

4.

Remove dial indicator from center housing oil

return (2) and position so indicator tip rests on

end of wheel and shaft assembly (3). Zero dial

indicator.

5.

Move wheel and shaft assembly (3) back and

forth. Maximum allowable end play is 0.004 in.

(0.102 mm).

b. DISASSEMBLY

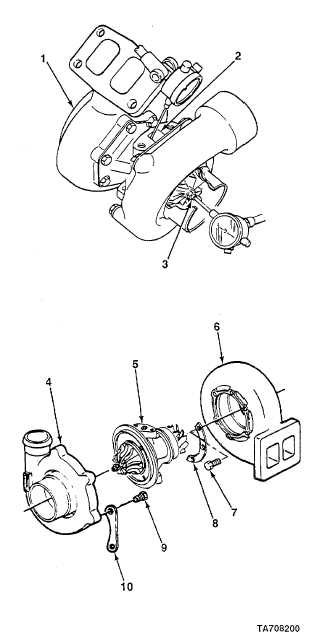

1.

Mark turbine housing (6), compressor housing

(4), and center housing (5) to aid during

assembly.

2.

Remove six screws (9), three lockplates (10),

and compressor housing (4) from center housing

(5).

3.

Remove six screws (7), two lockplates (8), and

center housing (5) from turbine housing (6).

5-56

|