| |

TM 10-3930-659-34

5-4.

ENGINE MAIN BEARINGS, THRUST BEARING, AND CRANKSHAFT REPLACEMENT.

This Task Covers:

a.

Removal

c.

Installation

b.

Cleaning and Inspection

Initial Setup:

Equipment Conditions:

Materials/Parts:

• Cylinder block front plate removed (see para-

• Crocus cloth (Item 8, Appendix B)

graph 5-6).

• Bearing clearance gage, blue (Item 31, Appendix B)

• Pistons and connecting rods removed (see para-

• Lubricating oil (Item 39, Appendix B)

graph 5-3).

• Lubricating oil (Item 40, Appendix B)

Tools/Test Equipment:

• Rags (Item 43, Appendix B)

• Dry cleaning solvent (Item 47, Appendix B)

• General mechanic's tool kit (Item 71, Appendix E)

• Wrecking bar (item 6, Appendix E)

Personnel Required: Two

• Inside caliper micrometer (Item 8, Appendix E)

General Safety Instructions:

• Outside caliper micrometer (Item 9, Appendix E)

• Dry cleaning solvent is flammable and must not be

• Compressor unit (Item 16, Appendix E)

used near open flame. Use only in a well-ventilated

• Dial indicator set (Item 19, Appendix E)

area.

• Mechanical puller (Item 51, Appendix E)

• Compressed air used for cleaning purposes should

• Stud remover and setter (Item 62, Appendix E)

never exceed 30 psi (207 kPa).

• Torque wrench, 0-175 lb.-ft. (Item 81, Appendix E)

References:

• TM 9-214

a.

REMOVAL

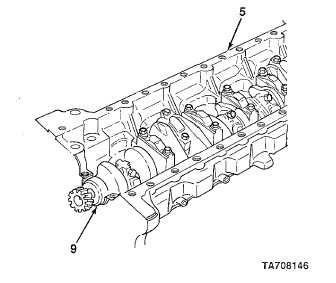

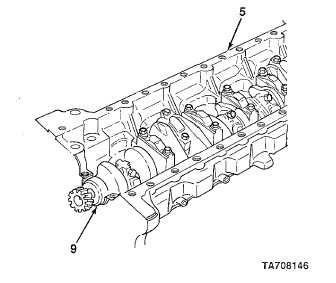

1.

Using wrecking bar and dial indicator, pry

crankshaft (9) forward in engine block (5).

Measure and note end play.

2.

Remove flywheel housing (see paragraph 4-10).

5-33

|