| |

TM 10-3930-659-34

5-1.

ENGINE BLOCK MAINTENANCE (Con’t).

19.

Torque 14 screws (16 and 20) to 85 lb.-ft. (115 N-m).

NOTE

Use bolt removed from crankshaft dampener to perform step 20.

20.

Install bolt (21) on crankshaft (22) and turn crankshaft two full revolutions. Crankshaft must turn freely. If

crankshaft does not turn freely, replace engine block (1).

21.

Remove bolt (21) from crankshaft (22).

22.

Remove two screws (20), washers (19), and thrust bearing cap (18) from engine block (1).

23.

Remove lower thrust bearing (24) from thrust bearing cap (18).

24.

Remove 12 screws (16), washers (15), and six main bearing caps (14) from engine block (1).

25.

Remove six lower main bearings (23) from main bearing caps (14).

WARNING

Use extreme caution when handling heavy parts. Lifting device is required when parts weigh over 50 lb

(23 kg) for a single person lift, over 100 lb (45 kg) for a two person lift, and over 150 lb (68 kg) for a three

or more person lift. Keep clear of heavy parts supported only by lifting device. Failure to follow this

warning may cause serious injury or death to personnel.

CAUTION

Ensure that crankshaft is lifted straight out of engine block. Crankshaft hitting against engine block may

damage parts.

26.

Using suitable lifting device, remove crankshaft (22) from engine block (1).

27.

Remove six upper main bearings (26) and upper thrust bearing (25) from engine block (1).

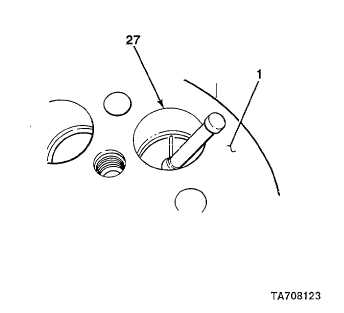

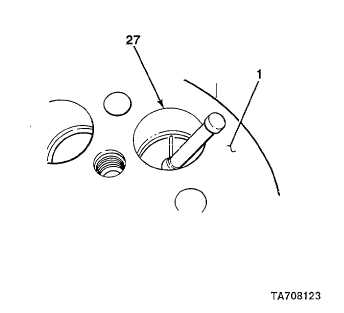

28.

Using inside caliper micrometer, measure inside

diameter

of

control

cam

bores

(27).

Measurement must be 1.248-1.250 in. (3.170-

3.175cm). If measurement is greater than

specification, replace engine block (1).

5-8

|