| |

TM 10-3930-659-34

2-22. LOCKWIRE (Con’t).

c. Three screws or bolts are the maximum number that may be lockwired in a series when they

are spaced 4-6 in. (10.2-15.2 cm) apart. The maximum number of closely spaced multiple groups of

screws or bolts to be lockwired is limited to the number of units that can be lockwired with a 24 in.

(61 cm) length of wire.

d. Do not secure screws, bolts, or fittings which are spaced more than 6 in. (15.2 cm) apart.

Lockwire these fasteners to tie points 6 in. (15.2 cm) or less away.

e. Lockwire parts so that tension will be on lockwire when parts tend to loosen. Lockwire should

be installed and twisted tight so that loop around head stays down and does not come up over head

of screw or bolt. This does not apply to castellated nuts when slot is close to top of nuts; wire is more

secure when made to pass along the side of stud. Ensure that lockwire is tight but not overstressed.

f. Make pigtail of 4-2 in. (6.4-12.7 mm) at end of lockwire. Bend pigtail down so it will not

become a snag.

g. When lockwiring castellated nuts, tighten castellated nut to low side of torque range, then

continue tightening until slot lines up with hole.

h. In blind, tapped hole application of bolts, castellated nuts, or studs, lockwir e as illustrated.

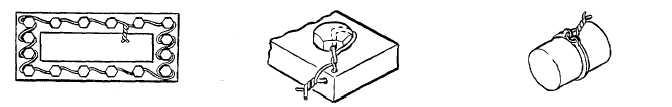

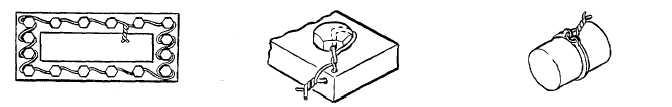

SMALL SCREWS IN CLOSELY SPACED,

CLOSED GEOMETRICAL PATTERN:

SINGLE

FASTENER

APPLICATION:

EXTERNAL RETAINER RING:

SINGLE WIRE METHOD

DOUBLE TWIST METHOD

SINGLE WIRE METHOD

CASTELLATED NUTS ON UNDRILLED STUDS: MULTIPLE FASTENER APPLICATION:

DOUBLE TWIST METHOD

DOUBLE TWIST METHOD

2-23. FLUID DISPOSAL.

Dispose of contaminated drained fluids in accordance with the Standard Operating Procedures

(SOP) of your unit.

2-13

|