| |

TM 10-3930-659-34

2-21. TUBES AND COMPRESSION FITTINGS.

a. Tubes with inverted nuts and compression fittings are designed for one time assembly. Once

assembled, they must be replaced as a unit if any parts are found defective. Used parts may not

seal properly when used with new ones.

b. Used tube assemblies in good condition can be installed to their original location without

leaking.

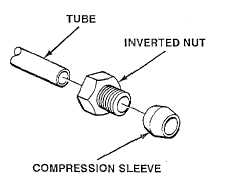

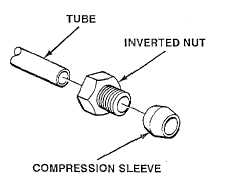

c. Assemble

new

tubes,

compression

sleeves, and inverted nuts as follows:

(1)

Slide inverted nut onto end of tube.

(2)

Slide compression sleeve onto end

of tube.

(3)

Repeat previous two steps for

other end of tube as required.

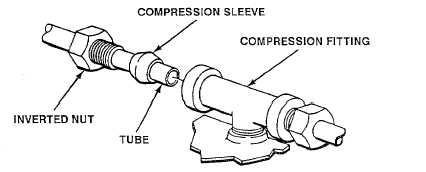

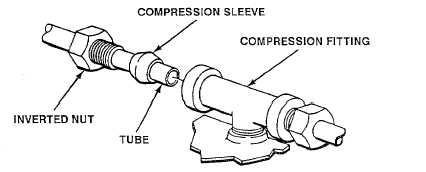

d. Install new tube assemblies as follows:

(1)

Insert end of tube as far as it will go into compression fitting to which tube is being

installed.

(2)

Twist Inverted nut into compression fitting and tighten inverted nut against compression

sleeve with open-end wrench (Item 71, Appendix E). Compression sleeve will clamp down around

tube and conform to internal surface of compression fitting and inverted nut.

(3)

Repeat previous two steps for other end of tube as required.

2-22. LOCKWIRE.

a. Always use nonelectrical wire (Item 59, Appendix B).

b. Drilled head screws and do Its usually do not require lockwiring if they are installed with self-

locking nuts or lockwashers.

2-12

|