| |

TM 10-3930-659-34

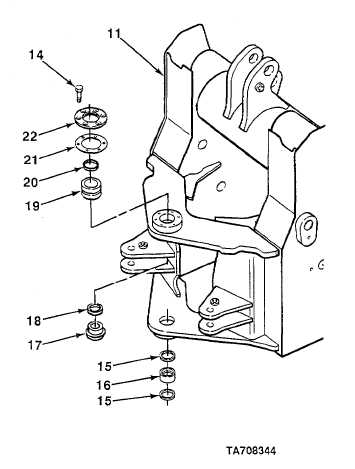

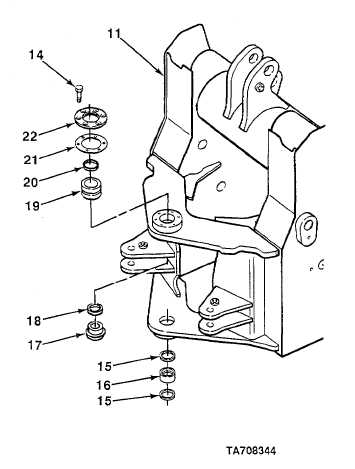

4-60. PIVOT PINS AND BUSHINGS REPLACEMENT (Con’t).

b. INSTALLATION

1.

Apply a coat of silicone compound to bore of loader frame (11) and outer surface of bushing (16).

2.

Press bushing (16) into loader frame (11) until Y4 in. (6 mm) from bottom surface.

3.

Press two new seals (15) in loader frame (11) until tight against bushing (16) with lips of seals facing outward.

4.

Apply a coat of grease to inner surface of bushing (16) and two seals (15).

5.

Apply a coat of grease to inner and outer surfaces of bearing (19).

NOTE

If installing new bearing, use new shims furnished with new bearing.

6.

Press bearing (19) into loader frame (11) until fully seated in bore of loader frame.

7.

Press new seal (20) into cover (22) with lip of seal facing outward and extending Y in. (3 mm) from cover.

8.

Apply a coat of grease to lip of seal (20).

9.

Press seal (18) into loader frame (11) with lip of seal facing downward.

10.

Apply coat of grease to lip of seal (18).

11.

Install cover (22) WITHOUT shims (21) on loader frame (11) with six screws (14). Tighten screws evenly until

cover contacts top of bearing (19).

12.

Using feeler gage, measure gap between cover (22) and loader frame (11).

13.

Assemble shim pack (21) with thickness of 0.001-0.005 in. (0.025-0.127 mm) LESS than gap measurement.

14.

Remove six screws (14) and cover (22) from loader frame (11).

15.

Install shim pack (21) and cover (22) on loader frame (11) with six screws (14). Torque screws to 105 lb.-ft. (142

N-m).

16.

Apply a coat of grease to inner and outer surfaces of nut sleeve (17).

17.

Install nut sleeve (17) in seal (18).

4-228

|