| |

TM 10-3930-659-34

Section XIII. FRAME MAINTENANCE

4-60. PIVOT PINS AND BUSHINGS REPLACEMENT.

This task covers:

a.

Removal

b.

Installation

INITIAL SETUP:

Equipment Conditions:

Materials/Parts:

• Forklift truck parked on a smooth, level, hard surface

• Silicone compound (Item 16, Appendix B)

with wheels straight ahead (see TM 10-3930-

• Grease (Item 33, Appendix B)

659-10).

• One locknut

• Parking brake set (see TM 10-3930-659-10).

• Two lubrication fittings

• Boom lock raised (see TM 10-3930-659-20).

• Four seals

• Steering valve removed (see TM 10-3930-659-20).

• Front universal joints and support bearing removed

Personnel Required: Three

(see TM 10-3930-659-20).

References:

Tools/Test Equipment:

• LO 10-3930-659-12

• General mechanic's tool kit (Item 71, Appendix E)

• TM 10-3930-659-10

• Feeler gage (Item 28, Appendix E)

• TM 10-3930-659-20

• Hydraulic jack, 10 ton (Item 39, Appendix E)

• Hydraulic jack kit (Item 40, Appendix E)

• Torque wrench multiplier (Item 44, Appendix E)

• Puller kit (Item 50, Appendix E)

• Trestle, 7 ton (two) (Item 73, Appendix E)

• Socket wrench set (Item 78, Appendix E)

• Torque wrench, 0-600 lb.-ft. (Item 82, Appendix E)

a. REMOVAL

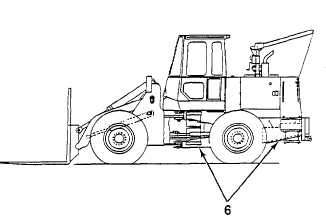

1. Position two trestles under rear of engine frame

(6).

2. Position wood cribbing under front of engine

frame (6).

TA708341

4-225

|