| |

TM 10-3930-659-34

4-29.

STARTER MOTOR REPAIR (Con’t).

WARNING

Compressed air used for cleaning or drying purposes, or for clearing restrictions, should never

exceed 30 psi (207 kPa). Wear protective clothing (goggles/shield, gloves, etc.) and use caution to

avoid injury to personnel.

4.

Using crocus cloth, clean and polish commutator of armature. Remove loose particles with compressed air.

5.

Using armature test set, test armature for shorting.

6.

Check brushes for excessive wear. Replace if broken or excessively worn. Full surface of each brush should

contact commutator of armature.

7.

Inspect brush springs for breaks and discoloration. Replace broken or discolored brush springs.

8.

Inspect threaded parts for damaged threads. Replace damaged parts.

9.

If removed, inspect wicks for damage. Replace damaged wicks.

10.

Inspect windings of field coil for damage or burned insulation. Replace damaged field coil.

c. ASSEMBLY

1.

Install insulator (64) on starter housing (4).

2.

Install insulator (58), four poles (59), and field coil (65) on starter housing (4) with seven new preformed packings

(60) and screws (61).

3.

Install new preformed packing (63) and terminal (62) on starter housing (4).

4.

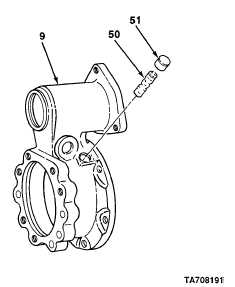

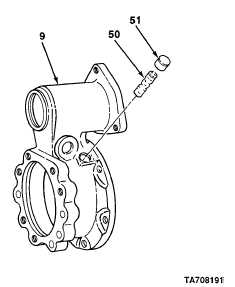

If removed, saturate wick (50) with lubricating oil. Install wick and new cup (51) on housing (9).

4-121

|