| |

TM 10-3930-659-34

4-6.

CYLINDER HEAD ASSEMBLY REPAIR (Con’t).

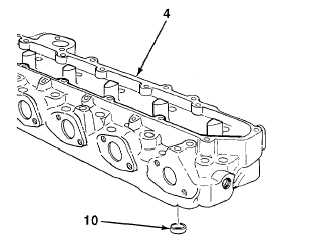

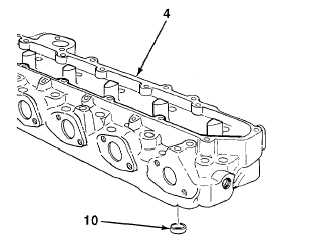

6.

Inspect 12 valve seat inserts (10) for cracks,

pits, and excessive wear. Replace damaged

valve seat inserts (see step 7).

NOTE

Perform step 7 only if valve seat

inserts are damaged.

7.

Using valve seat puller, remove valve seat insert

(10) from cylinder head (4).

WARNING

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective goggles and gloves, and

use only in a well-ventilated area. Avoid contact with skin, eyes, and clothes, and DO NOT breathe vapors.

DO NOT use near open flame or excessive heat. The solvent's flash point is 100°F-138°F (38°C-59°C). If

you become dizzy while using cleaning solvent, immediately get fresh air and medical help. If solvent

contacts eyes, immediately wash your eyes and get medical aid.

8. Clean valve springs, valve spring retaining lock, and rotators with dry cleaning solvent and dry with clean rags.

9. Inspect cylinder head valves and valve springs for damage. Replace damaged parts.

10. Inspect rotators for proper movement. Rotators must turn freely in both directions. Replace defective rotators.

11. Using spring tester and torque wrench, compress valve springs to 1.81 in. (4.60 cm) and note compression force

on torque wrench. Compression force must be 54-62 lb.-ft. (73-84 N.m). Replace valve springs not within

specification.

12. Using spring tester and torque wrench, compress valve springs to 1.36 in. (3.45 cm) and note compression force

on torque wrench. Compression force must be 133-135 lb.-ft. (180-183 Nom). Replace valve springs not within

specification.

TA708069

4-23

|