| |

TM 10-3930-659-34

4-2.

CYLINDER HEAD VALVE LIFT CHECK (Con’t).

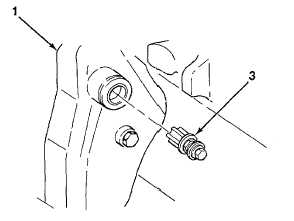

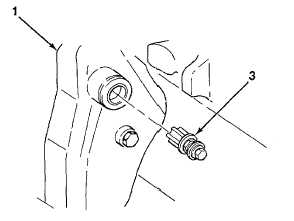

2.

Install flywheel turning tool (3) on engine (1).

NOTE

Cylinder head valve lift is checked the same way for all cylinder head

valves. One cylinder head valve is illustrated.

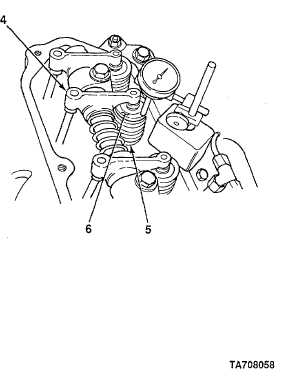

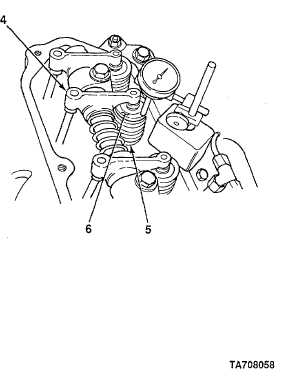

3.

Using flywheel turning tool (3), rotate flywheel until there is clearance between engine rocker arm (4) and cylinder

head valve (5).

4.

Install dial indicator on cylinder head valve (5) with

stylus against cylinder head valve rotator (6). Zero

dial indicator.

5.

Using flywheel turning tool (3), rotate flywheel and

note reading on dial indicator when clearance

between engine rocker arm (4) and cylinder head

valve (5) is fully opened. Intake cylinder head valve

lift measurement must be 0.4600.490 in.

(11.68412.446 mm) and exhaust cylinder head valve

lift measurement must be 0.4560.482 in.

(11.58212.243 mm). If measurements are not within

specification, inspect cylinder head valves (see

paragraph 4-6), engine rocker arm assembly and

pushrods (see paragraph 4-12), and tappets (see

paragraph 4-13).

6.

Remove dial indicator from cylinder head valve (5).

7.

Repeat steps 4 through 6 for remaining cylinder

head valves.

8.

Remove flywheel turning tool (3) from engine (1).

9.

Install plug (2) on engine (1).

FOLLOW-ON TASKS:

•

Install engine rocker arm cover (see TM 10-3930-659-20) 4-5

TA708058

4-5

|