| |

TM 10-3930-659-34

4-1.

ENGINE ASSEMBLY COMPRESSION TEST (Con’t).

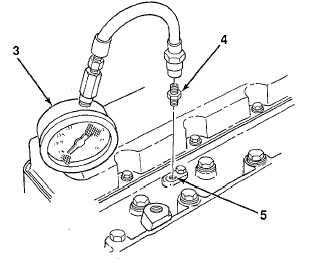

3.

Install adapter (4) and cylinder compression tester

(3) in fuel injection nozzle bore (5).

WARNING

Stay clear of rotating fan blades when

cranking engine. Failure to follow this

warning may result in serious injury to

personnel.

CAUTION

DO NOT operate starter motor for more

than 20 seconds at a time. Allow two

minutes for cooling before using starter

motor again or

starter

motor

may

overheat.

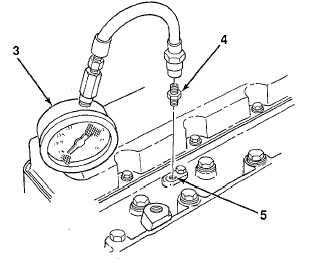

4.

Using ignition switch, crank engine assembly with

starter motor for four revolutions of engine and note

compression reading on cylinder compression tester

(3).

5.

Remove cylinder compression tester (3) and adapter

(4) from fuel injection nozzle bore (5).

6.

Repeat steps 3 through 5 for remaining fuel injection nozzle bores (5). Compression readings must be greater than

350 psi (2413 kPa) and difference between highest and lowest compression readings must be less than 50 psi (344

kPa). If compression readings are within specification, proceed to step 9.

7.

Using hand oiler, apply four squirts of lubricating oil on piston rings on cylinder being tested through fuel injection

nozzle bore (5).

8.

Repeat steps 3 through 5. If compression reading is below specification, worn or sticking valves or head gasket are

indicated. If compression reading is higher than previous compression reading, worn or sticking piston rings are

indicated.

9.

Install fuel injection nozzles (see paragraph 4-23).

10. Connect fuel injection pump connector (1) to connector (2).

FOLLOW-ON TASKS:

•

Close right and left engine upper sideshields (see TM 10-3930-659-10).

•

Install conveyorized fork attachments on side of forklift truck (see TM 10-3930-659-20).

TA708056

4-3

|