| |

TM 10-3930-659-20

2-28.

ELECTRICAL REPAIR (Con't).

k.

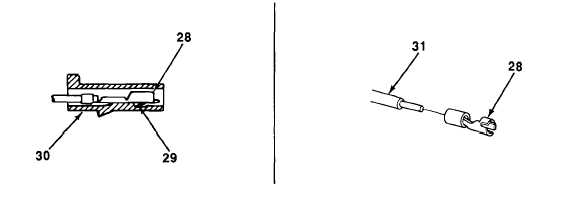

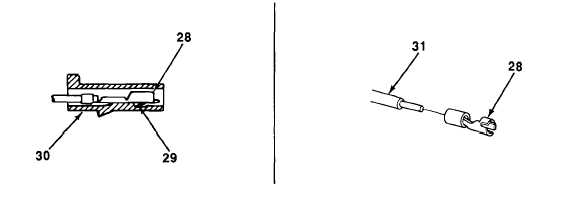

Connector Body Terminal Replacement.

(1)

Depress locking tang (29) on terminal (28).

(2)

Slide connector body (30) off terminal (28).

(3)

Cut terminal (28) off wire lead (31) and discard.

(4)

Remove Insulation from wire lead (31) equal to depth of new terminal (28).

(5)

Position new terminal (28) on wire lead (31) and crimp (Item 43, Appendix F).

(6)

Bend locking tang (29) on terminal (28) to original position.

(7)

Install terminal (28) on connector body (30).

2-29.

HYDRAULIC SYSTEM WARM-UP

a.

This procedure is to be performed when hydraulic system warm-up is required for maintenance reasons and

under normal conditions.

(1)

Start engine (see TM 10-3930-659-10).

(2)

Slowly cycle lift, tilt, and spacing functions of forklift truck a number of times.

(3)

Slowly turn steering wheel in either direction until steer limit is reached. Hold steering wheel in position

for a short time.

(4)

Turn steering wheel in other direction until steer limit is met. Hold steering wheel in position for a short

time.

(5)

Repeat this procedure until hydraulic fluid reaches normal operating temperature.

(6)

Shut down engine (see TM 10-3930-659-10).

b.

If hydraulic system warm-up is required in extreme cold situations, extra precautions and requirements must

be performed (see TM 10-3930-659-10).

TA706730

2-25/(2-26 Blank)

|