| |

TM 10-3930-653-14&P

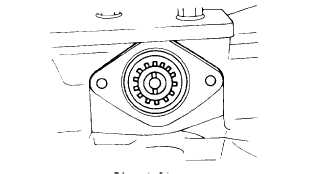

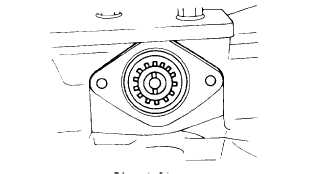

Fig. 4-93.

(4) Install hydraulic oil pump chain cover with gasket in

place.

(14) INSTALLING CRANK PULLEY

Align the pulley key slot with the key on the

crankshaft, fit the pulley, and secure the crank pulley

bolt.

Tightening torque:

Crank pulley bolt

12 to 16 kg-m

(87 to 116 ft-lb)

(15) INSTALLING OIL PUMP

The distributor is driven by the oil pump through the

oil pump pinion. Ignition timing is changed according to

the installing direction of the gear.

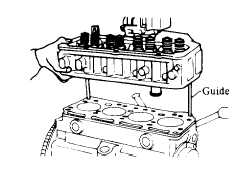

(1) Turn oil pump so that narrow portion on top of drive

pinion gear faces to front when No. I cylinder Is set to

compression top dead center (TDC) position and align oil

pump with set bolt position.

Install oil pan end first.

Fig. 4-94. Drive Gear Position.

(2) Apply Loc-TiteÒ seal to set bolt and install It in hole

in pump body and tighten bolt securely and lock with lock

nut.

(3) Install oil pan with oil pan gasket

Tightening torque:

Oil pan

0.4 to 0.7 kg-m

(2.9 to 5.1 ft-lb)

Drain Plug

4.5 to 5.0 kg-m

(33 to 36 ft-lb)

(16) INSTALLING CYLINDER HEAD

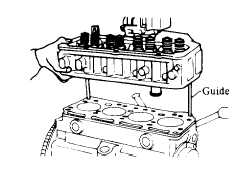

(1) Install guide bolts on both sides of cylinder block.

(2) Install new cylinder head gasket.

(3) Place cylinder head over guide bolts, and install on

block.

Fig. 4-95. Installing Cylinder Head.

(4) Install cylinder head bolts, tighten them in sequence

shown below (tighten alternately and evenly, gradually

tightening in 3 or 4 stages) and finally tighten them to

prescribed tightening torque.

Temporary tightening torque:

Cylinder head bolts

6.5 kg-m (47 ft-b)

Tightening torque:

Cylinder head bolts

8.0 to 8.5 kg-m

(58 to 61 ft-lb)

4-48

|