| |

TM 10-3930-653-14&P

Fig. 4-64. Main Bearing Caps and Bearings

(2) Measuring lubrication

(oil) clearance

(1) Measure lubrication (oil) clearance with a width

gauge (plastigage). For applicable instructions, refer to

paragraph on lubrication (oil) clearance measurement for

connecting rod bushing.

Tightening torque:

Bearing cap

8.5 to 9.5 kg-m

(61 to 69 ft-lb)

(2) If lubrication (oil) clearance exceeds prescribed limit,

select an appropriate replacement part from service

parts, checking crank-journal diameter.

Service (clearance)

Correct to within

limit

Main bearing

lubrication

0.02 to 0.062

0.1 (0.0039)

(oil) clea-

(0.0008 to 0.0024)

rance

mm (In)

Main bearing bushing specifications

Undersize mm (in)

Crank journal dia. mm (in)

62.692 to 62.705

0.25 (0.0098)

(2.4682 to 2.4687)

62.422 to 62.455

0.50 (0.0197)

2.4576 to 2.45)

62.192 to 62.205

0.75 (0.0295)

(2.4485 to 2.4490)

61.942 to 61.955

1.00 (0.0394)

(2.4387 to 2.4392)

4-2-4-11.

CAMSHAFT

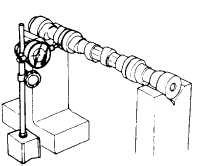

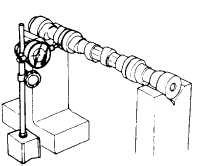

(1) CHECKING CAMSHAFT FOR

BENDING

Measure the camshaft for bending and, If beyond

prescribed bend limit, correct with a press or replace with

a new camshaft. For measurement, support the

camshaft on V-blocks at each end, as shown in Fig. 2-

53 (1/2 of the maxi-mum value shown on the dial gauge

is the amount of bend).

Fig. 4-65. Measuring Camshaft Bending

Service (bend)

Correct to within

limit

Camshaft

bending

0.02 (0.0008)

0.05 (0.0020)

mm (in)

4 - 38

|