| |

TM 10-3930-653-14&P

4-2-4-3.

CYLINDER HEAD

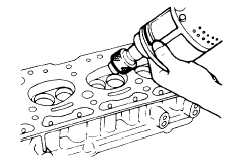

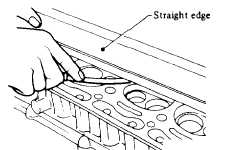

(1) REMOVING CARBON

Remove carbon from the combustion chamber of the

cylinder head and from the side surface on which the

manifold is installed and check for scars or damage.

Fig. 4-36. Cleaning Cylinder Head

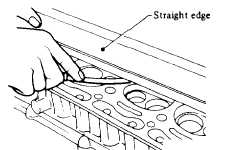

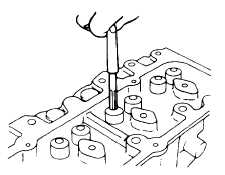

(2) MEASURING CYLINDER

HEAD FOR WARPAGE

Measure

the

cylinder

head

surface

for

both

longitudinal

and

transverse

warpage.

If

uneven

(warpage exceeds prescribed limit). correct the surfaces

with a mill grinder.

Fig. 4-37. Measuring Cylinder Head

Fire Deck (Block Contact Surface)

for Warpage

Surface flatness

Less than

mm (in)

0.1 (0.004)

Grinding limit

mm (in)

2.0(0.08)

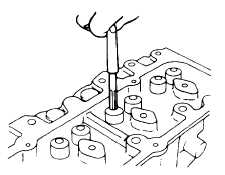

(3) REAMING VALVE GUIDES

Measure valve stem and valve guide clearance If

clearance exceeds prescribed limit. ream out the valve

guide and install valves with oversized stems. Two types

are provided (for intake and exhaust valves): .20mm and

.40mm oversizes.

Fig. 4-38. Reaming Valve Guide

Standard

Service limit

clearance

Clearance

0.028 to

(Intake)

0.030

0.10

Valve stem/

(0.0011 to

(0.0039)

valve guide

0.0012)

clearance

0.058 to

mm (in)

(Exhaust)

0.060

0.15

(0.0023 to

(0.0059)

0.0024)

Intake valve stem dia.

mm (in)

Exhaust valve stem dia

mm (in).

8.657 to 8.670

8.627 to 8.640

STD

(0.3408 to 0.3413)

(0.3396 to 0.3402)

8.857 to 8.870

8.827 to 8.840

20

(0.3487 to 0.3492)

(0.3475 to 0.3480)

9.057 to 9.070

9.027 to 9.040

40

(0.3566 to 0.3571)

(0.3554 to 0.3559)

4 - 28

|