| |

TM 10-3930-653-14&P

4-1-3 ENGINE TUNE-UP

4-1-3-1. DESCRIPTION

To restore power and performance that has been lost

through wear, corrosion, or deterioration, periodic

maintenance (engine tune-up) is necessary.

It is Important that the engine tune-up be done

accurately according to the maintenance schedule

shown in section four ( 4) of this manual.

This chapter describes actual operating procedures

for the maintenance operation of items to be inspected.

4-1-3-2. BASIC MECHANICAL

SYSTEM

(1)

RETIGHTENING CYLINDER HEAD BOLTS,

MANIFOLD BOLTS AND NUTS

Cylinder head bolts and valve rocker shaft bracket

bolts:

When the engine is cold, tightening should be made

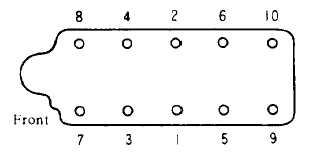

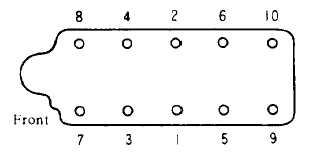

In several steps and in the sequence shown in Fig. 1-1.

starting with the center and moving toward the ends.

Fig. 4-1. Tightening Sequence of

Cylinder Head Bolts.

Tightening torque:

Cylinder head bolts

8.0 to 9.5 kg-m

(59 to 69 ft-lb)

When the engine is warm, tighten the bolts and nuts

to a torque of 0.5 kg-m ( 3.6 ft-lb) higher than the

specifications shown above

Intake and exhaust manifold bolts and nuts should be

tightened to the specified torque, shown below.

Tightening torque:

Intake and exhaust manifold

1.4 to ;.8 kg-m

(10 to 13 ft-lb)

(2)

ADJUSTING INTAKE AND EXHAUST VALVE

CLEARANCES

Valve clearance adjustment should be made while

engine is not running.

To adjust. proceed as follows

(1)

Start engine and run it until it is heated to

operating temperature. or at least, more than 80 C (176°

F). then stop engine.

(2)

Rotate crankshaft to bring No. 1 cylinder to top

dead center on its compression stroke. ( Number 1

cylinder is the one closest to the fan).

( 3)

Remove al e rocker cover to gain access to

valve operating mechanism.

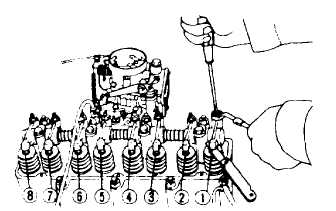

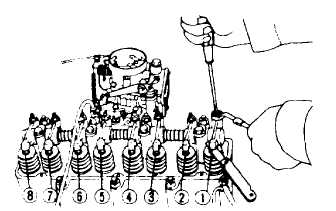

Adjust valve clearance at the following four

points while engine is still hot.

a. Exhaust valve of No. 1 cylinder

(l)

b. Intake valve of No. 1 cylinder

(2)

c. Intake valve of No. ’2 cylinder

(3)

d. Exhaust valve of No. 3 cylinder

(5)

Note: Encircled numbers agree with

those in accompanying sketch.

Fig. 4-2. Adjusting Valve Clearance.

(4)

Rotate crankshaft one complete turn so that the

No. 4 piston is on top dead center of its compression

stroke. Adjust the following valves:

e. Exhaust valve of No. 2 cylinder

(4)

f. Intake valve of No. 3 cylinder

(6)

g. Intake valve of No. 4 cylinder

(7)

h. Exhaust valve of No. 4 cylinder

(8)

4 - 8

|