| |

TM 10-3930-653-14&P

[3] TIRE INFLATION PRESSURE CHECK

Check condition of tires. Low air pressure reduces tire

service life and increases fuel consumption. Uneveness

of air pressure between right and left tires or unevenly

worn or badly damaged tires will cause uneven steering

forces.

< Inflation Pressure >

kg/cm2 (psi)

Sinqle Drive Wheels ..........................................8,5 (120)

Steering Wheels ...................................................7 (100)

Turn the tire valve cap counterclockwise and remove it.

Using a tire pressure gauge, measure the inflation

pressure, and adjust it to the specified pressure, if

needed. After making sure there is no air leakage from

the tire valve, reinstall the cap.

Check that each tire does not get damaged at the tread

surface or side face or there is no bending at the rim,

Since the forklift truck needs tires that have a high

inflation pressure to carry heavy loads, even a small

bending of rims or damage at the tread surface could

cause an accident. If the operator finds any defect on

the tires, consult TCM’s dealer or distributor.

WARNING

All nuts and bolts should be properly installed and

torqued before inflating tire and rim assembly, An inflated

tire contains potentially explosive energy.

DON’T OVERINFALTE.

WARNING

When using an air compressor, first adjust the air

pressure of the compressor. Failure to do so will cause

a serious accident, since the compressor delivers the

maximum pressure.

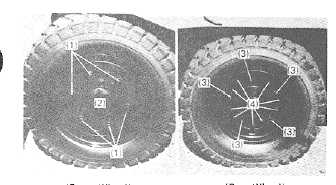

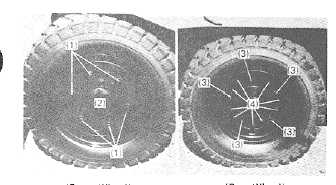

[4] HUB NUT TORQUE CHECK

Check hub nuts for correct torque. All hub nuts should

be tightened to the specified torque securely.

(1) Front Wheel Hub Nut.......................... 39 to 45 kg-m

(282 to 325 ft-lbs)

(2) Drive Shaft Nut .................................. 7.8 to 9.0 kg-m

(56 to 65 ft-lbs)

(3) Rear Wheel Hub Nut ........................... 39 to 45 kg-m

(282 to 325 ft-lbs)

(4) Rear Wheel Divided Rim Nut........... ..6.6 to 7.6 kg-m

(48 to 55 ft-lbs)

(Front Wheel) (Rear Wheel)

WARNING

• When removing tire assembly from the truck, remove

only HUB NUTS 3. Never loosen split type wheel nuts

4before deflating tires.

• Completely deflate tires before removing split type

wheel nuts 4,

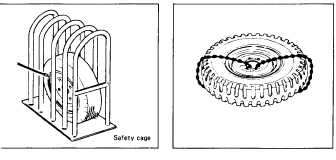

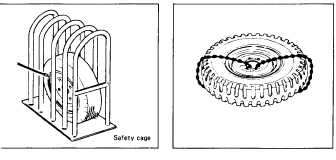

• Tires with split wheels should be inflated in a safety

cage or when properly Installed on the truck In either

case, make sure all nuts and bolts are properly Installed

and torqued as specified

• If wheel nuts on the drive axle are loose, tighten nuts to

specified torque after removing tire and wheel assembly

from the truck.

• Tires with lock ring type wheels should be Inflated in a

safety cage or with attaching safety chain

• Stop the truck on a level, hard surface and shut down

the engine. All loads should be unloaded from the

truck.

• Apply the parking brake and block the wheels. Put the

jack under the truck frame.

• Jack up the truck to the extent that the tire still remains

on the ground. Loosen the hub nuts Do not remove

them.

• Again jack up the truck until the tire leaves off the

ground. Remove the hub nuts, and detach the wheel.

• The wheel should be reinstalled in the reverse order

The hub nuts should be tightened in the diagonal order

evenly.

2-9

|