| |

TM 10-3930-653-14&P

(3)

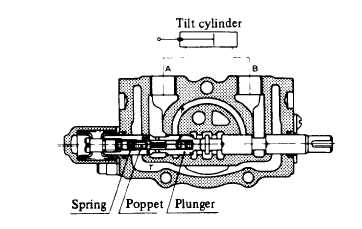

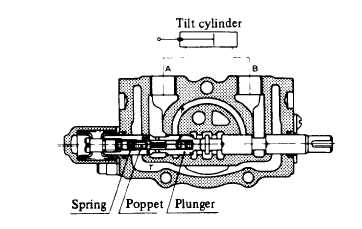

Operation of Tilt Lock Valve

The tilt-lock valve is intended to prevent vibrations of the mast due to possible creation of internal negative

pressure in the tilt cylinder and also to avoid danger incurred from mis-handling of the lever. On the conventional model,

even if the engine is off, the mast can be tilted forward by actuating the tilt lever. But this newly adopted tilt-lock valve does

not allow the mast to tilt forward as long as the engine is shut off, even if the tilt lever is pushed with the full load. Refer to

Fig. 16-9 for the construction of the tilt-lock valve.

The port " A" side of the plunger housing is led to the front side of the tilt cylinder, and the port "B" side to its rear

side. When the tilt lever is pulled backward (plunger drawn out), the oil from the pump flows into the port "A" while the port

"B" side oil returns to the tank, so that the mast is tilted backward by the tilt cylinder.

When the tilt lever is pushed forward (plunger pressed), the oil from the pump flows into the port "B". But in the

port "A" side, oil does not return to the tank, unless the poppet installed in the plunger is moved. In other words, the mast

would not tilt forward unless the oil pressure at the rear side of the tilt cylinders reaches a certain level. Hence, while the

engine is being shut down, the mast never tilts forward, nor does the internal pressure in the tilt cylinders become

negative.

Fig. 4-474. Tilt Lock Valve

4-238

|