| |

TM 10-3930-653-14&P

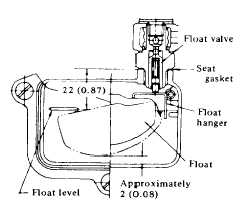

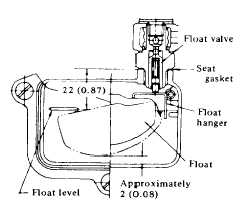

(2) ADJUSTMENT OF FLOAT LEVEL

Adjust the position of float (up position). Place the

body horizontally with float chamber facing upwards and

keep the body inclined 10 to 15° downwards at upper

side of float chamber. The float then should be

horizontal.

Adjustment is made by increasing or decreasing the

metal plate gaskets at the float valve seat.

Adjust the position of float (down position).

Keep float chamber in its original posture and lower the

float naturally.

Adjustment is made by bending float stopper.

Refer to Fig. 5-4.

Fig. 4-119. Adjusting Float Level.

(3) IDLE ADJUSTMENT

(1) Check to be sure that the float level is correct while

engine is at idle speed.

(2) Using a suitable screwdriver, turn out idle adjusting

screw approximately two or three turns, starting from

fully closed position. Turn in throttle adjusting screw two

or three turns and start engine.

(3) Turn out throttle adjusting screw gently until specified

engine idle speed is approximately obtained.

Turn idle adjusting screw in or out until engine runs

smoothly at highest speed.

(5) Turn out throttle adjusting screw until specified

engine speed is obtained.

(6) Readjust idle adjusting screw until engine runs

smoothly at the highest speed (with the highest vacuum

reading).

(7) Then, throttle adjusting screw must be adjusted so

that engine speed is 20 rpm faster than specified.

(8) Finally, turn in idle adjusting screw until specified

engine speed is attained.

WARNING

Carbon monoxide gas is a colorless,

odorless,

poisonous,

deadly

gas

produced by incomplete combustion

of any carbon containing material.

It occurs in the exhaust fumes of fuel

burning internal combustion engines,

and

becomes

dangerously

concentrated under conditions of

inadequate ventilation.

Note:

a. Items (7) and (.8): Best method to reduce carbon

monoxide in exhaust emission.

b. Do not attempt to screw down idle adjusting

screw completely. If screw tip is damaged, it will

cause engine malfunctions.

Engine idle speed rpm

550

Engine manifold

vacuum at idle

speed

mmHg (inHg)

-430

(-16.9)

(4) JET

The larger numbers punched on jets to measure

gasoline indicate richer fuel-air mixture, and the smaller

numbers indicate leaner mixture. Main and slow air

bleeds are provided with passages to let air in to make

lean fuel-air mixture.

The larger numbers indicate leaner mixture, and the

smaller numbers indicate richer mixture.

This should be noted when the conditions require a

change of mixture, such as high altitude.

4-70

|