| |

TM 10-3930-653-14&P

Standard type

Frigid type

Valve opening

Temperature

76.5 (170)

88 (190)

C ( F)

Maximum valve

lift mm/°C

8/90 (0.31/194)

7/1100(0.28/212)

(in/ F)

4-4-3-4. RADIATOR

The radiator is a conventional cross flow type having

right and left tanks to distribute the coolant flow uniformly

through the horizontal tubes of the radiator's core.

The radiator filler cap is designed to maintain a pre-

set pressure 0.9 kg/cm2 (13 psi) above atmospheric

pressure. The relief valve consisting of a blow-off valve

and a vacuum valve, helps to prevent coolant loss from

boiling by raising the pressure on the coolant. On the

other hand as the pressure is reduced below

atmospheric pressure the vacuum valve allows air to re-

enter the radiator, preventing the formation of a vacuum

in the cooling system.

The left tank on lift trucks equipped with an

automatic transmission incorporates an oil cooler for the

transmission fluid.

(1) REMOVAL AND INSTALLATION

(1) Drain coolant into a clean container.

(2) Remove top panel.

(3) Remove engine hood.

(4) Disconnect radiator upper and lower hoses. On

models with automatic transmission, disconnect cooler

inlet and outlet lines from radiator.

(5) If equipped, remove radiator shroud retaining bolts

and remove radiator shroud.

(6) Remove radiator retaining bolts and then remove

radiator upward.

(7) Install radiator in the reverse sequence of removal.

Note the following:

a. Insert hoses in their positions until they bottom.

b. Ensure that arrow marks on hoses are clearly

visible from above when hoses are assembled.

c. Ensure that clearance between shroud and fan

is even.

Note:

Be careful not to damage radiator fins

and core tubes when installing.

(2) INSPECTION

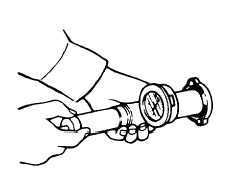

Radiator cap should be checked for working

pressure at regular tune-up intervals. First, check rubber

seal on cap for tears, cracks or deterioration after

cleaning it. Then, install radiator cap on a tester. If cap

does not hold or will not release at the specified

pressure, replace cap.

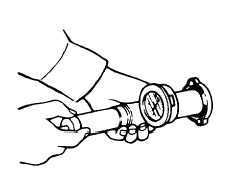

Fig. 4-114. Testing Radiator Cap.

Also, inspect radiator for leakage using cap tester

and applying a pressure of 1.6 kg/cm2 (23 psi).

If leakage is detected, repair or replace radiator.

4-60

|