|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

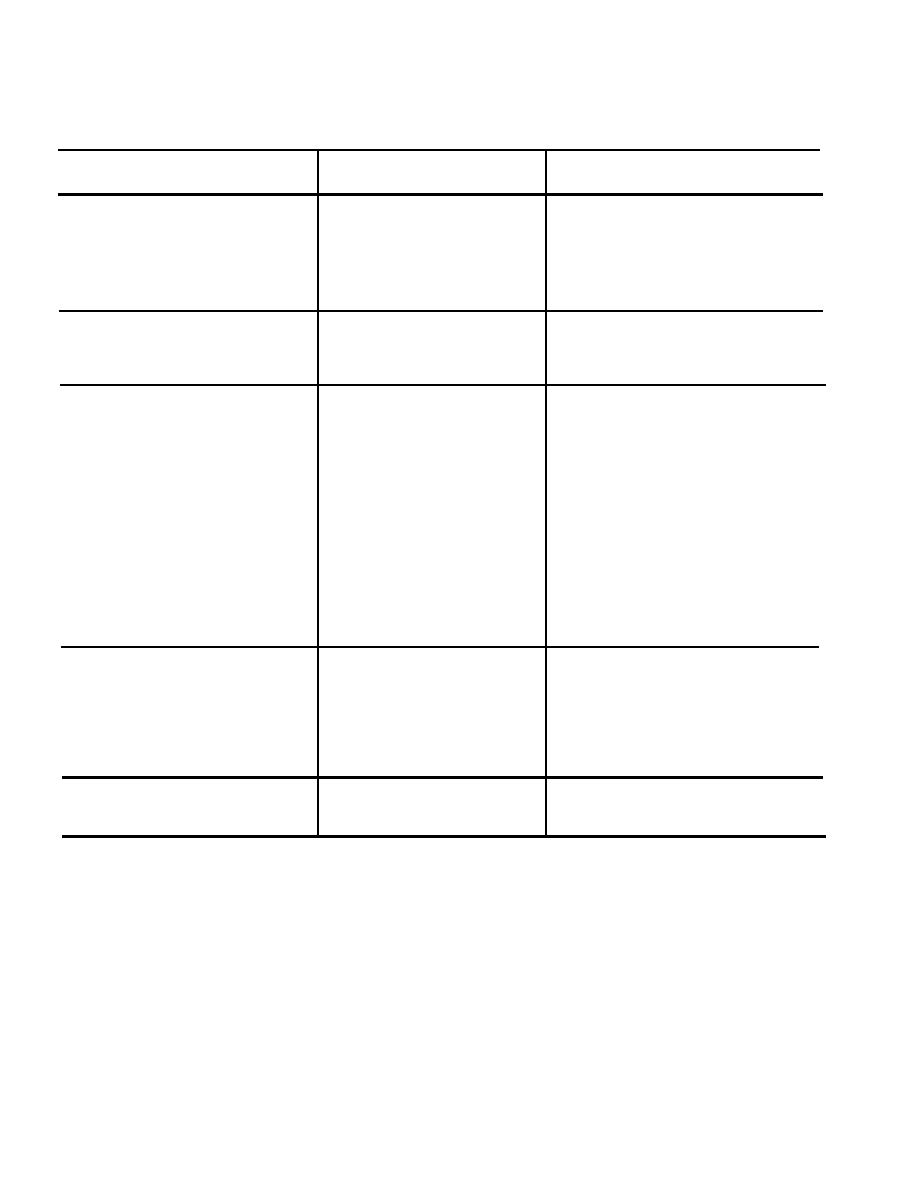

REMEDY

PROBABLE CAUSE

TROUBLE

a. Fill reservoir

a. Low oil supply

Noisy Pump

1.

b. Change to proper

b . Oil too heavy,

(i.e. viscous)

viscosity

c. Air leak in inlet line

c. Check plumbing

d . Partly blocked inlet

d . Check for foreign object

line

and/or clean

a. See 1a, 1b, 1c, 1d

Foaming Oil

a. Pump cavitating

2.

b. Check reservoir and/or

b . Water in the oil

heat exchange

a. Drain & fill with proper

a . Oil supply too thin

Pump or oil overheating

3.

viscosity oil

b. Drain, clean filter, & fill

b. Oil supply contaminated

with clean oil

c. Pump cavitating

c. See 1a, 1b, 1c, 1d

d. Check alignment

d. Pump drive shaft exces-

sively misaligned with

pump driven shaft

e. Check for clearance at ends

e. Pump drive shaft axially

o f shafts, for shaft mis-

loaded by driving shaft

alignment or worn driving

(Prime Rover)

keys, keyways or splines.

If pulley drive check for

belt alignment

f . Check relief valve setting

f . System relief valve by-

(see 4c)

passing

a. Pump cavitating

a. See 1a, 1b, 1c, 1d

4. Low Flow

b. See 2a, 2b

b. Foaming oil

c. Check relief valve for

c . Relief valve leaks or

f o r e i g n particles

set too low

d . Speed too low

d. Check prime mover speed

e. Check temperature (see 3a,

e. Oil too hot

3 b , 3 c 3d & 3e)

a . Defective Relief valve

a. Check and reset or replace

Failure to build

5.

b. Low oil supply

b. Fill reservoir

pressure

NOTE

Always check the TROUBLE SHOOTING LIST before a pump is

removed or disassembled.

5-92H

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |