|

|||

|

|

|||

|

Page Title:

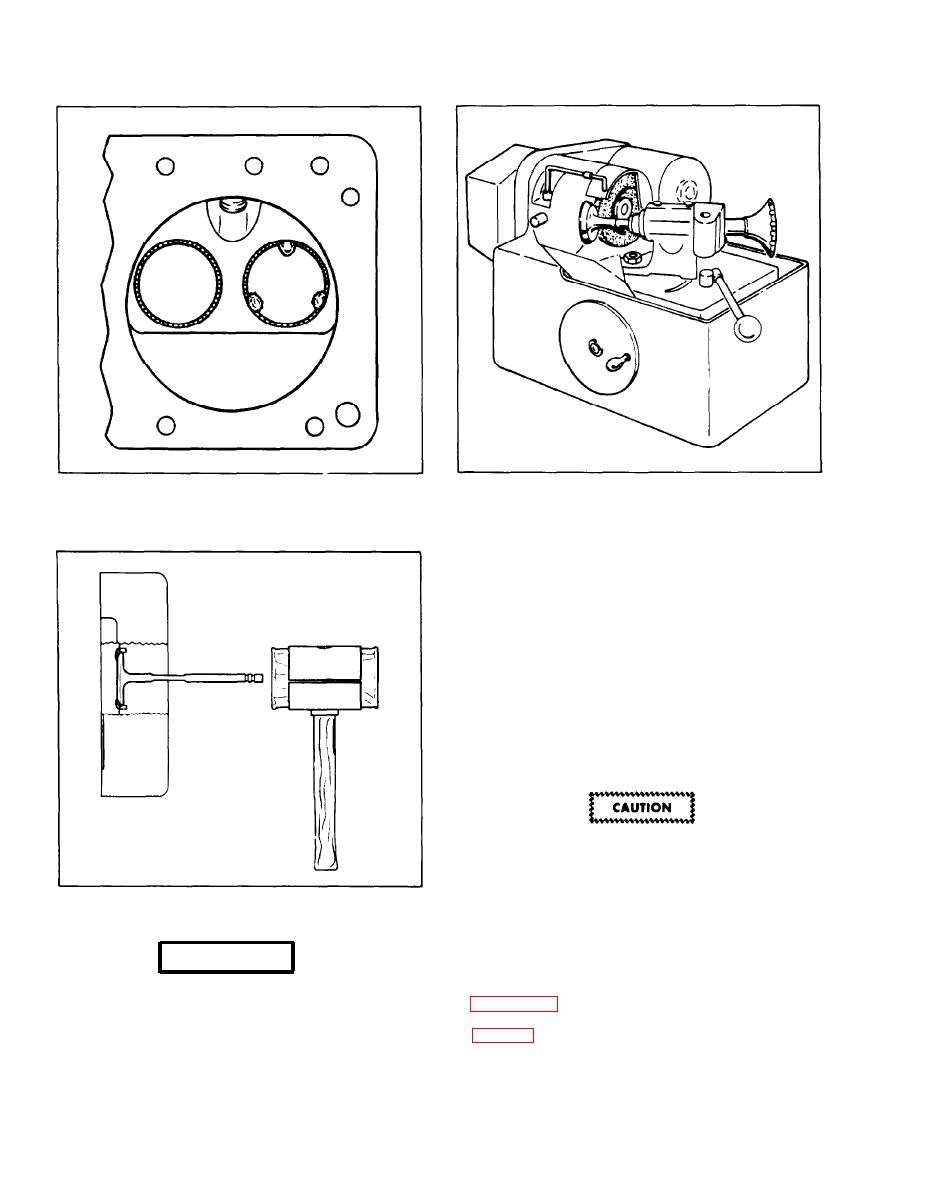

Figure 5-26. Scrap Valve Welded In Place |

|

||

| ||||||||||

|

|

Figure 5-26. Scrap Valve Welded In Place

Figure 5-28. Valve Grinding Machine

cause serious freezing. Use gloves and

forceps or bent wire to remove metal parts.

Never touch metal that has been in dry ice

until temperature has risen above the

freezing point.

m. Using a pair of forceps or a hooked wire (see

warning), quickly lift the chilled insert from the

dry ice and locate it over the counterbore so the

lower edge is entered squarely. Start the driving

tool pilot in the valve guide, bringing the driving

face against the insert upper surface accurately,

and tap the tool with a medium weight hammer.

If severe hammering seems to be required,

the counterbore is not clean or has burrs,

t h e insert is not chilled enough, or not

Figure 5-27. Driving Out Seat

started into the counterbore straight and

true.

WARNING

5-33. VALVE GRINDING (Refacing).

a. A valve grinding device similar to that shown

in figure 5-28 will be required to reface the valves

Dry ice is a solid with an extreme low

at the proper angle according to the specifications

t e m p e r a t u r e . Contact with the skin will

of Table 5.

5-24

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |