|

|||

|

|

|||

|

Page Title:

Figure 4-89. Checking Roller Angle |

|

||

| ||||||||||

|

|

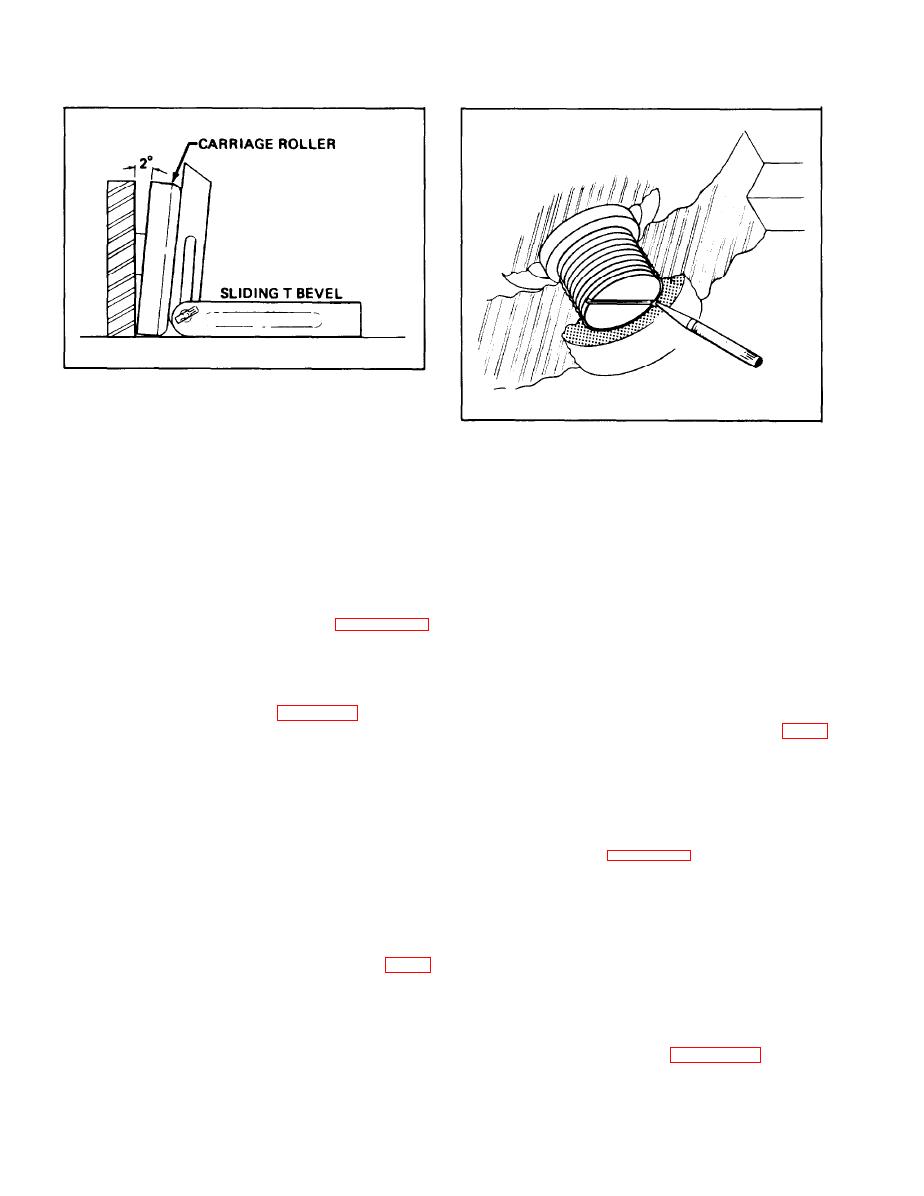

Figure 4-89. Checking Roller Angle

are in place, raise inner rail enough to install the

Figure 4-90. Securing Outer Thrust Roller

stop block behind the inner rail.

d. Span upper carriage rollers

4-84. CARRIAGE ROLLER ADJUSTMENT.

c h e c k i n g across the upper outside of the

Carriage roller adjustment will require removal of

roller (outermost camber point). Add or subtract

the carriage. Refer to paragraph 5-140 for

s h i m s behind rollers until the span across the

carriage removal procedures.

rollers is equal to the inner rail span, less l/16 inch

total. The l/16 inch clearance must not be

4-86. TOOLS REQUIRED. Special measuring

e x c e e d e d . No more than l/32 inch clearance is

devices called spanners are required to perform the

permissible over the roller on each side.

carriage roller adjustments. Refer to figures 4-87

and 4-88 for details of construction.

4-87. CENTERING ADJUSTMENT.

4-86. CLEARANCE ADJUSTMENT.

a. Check outer thrust rollers for wear and loose

mounting studs. If bearings are worn, replace, If

a. Use inside spanning tool, figure 4-87, to check

loose, tighten and stake in place as shown in figure

the distance between the inner rails at every ten

4-90.

inches over their entire length. Lock the tool at the

smallest span obtained.

b . Center the carriage roller within the outer

t h r u s t rollers by placing a 6-inch scale on the

Note

carriage roller surface and measuring the distance

to the outer thrust roller face. Check this distance

Measurements must be taken inside the

on both sides. (See figure 491.)

rails, not on the edges, and the spanning

tool must be held perpendicular to the

c. Transfer shim from one side to the other to

rails.

make the measurement equal on both sides. Do not

r e m o v e a shim from one side without replacing

b. Use a sliding "T" bevel to check angle of the

that shim on the opposite side.

carriage rollers. This angle must be 2 1/2. If

not, the roller pin must be replaced. (See figure

4-88. SQUARING ADJUSTMENT.

489.)

a. Check for an out-of-square condition by

c. Set outside spanning tool to match span of the

placing a carpenter's square over the rollers and

inside spanning tool, and lock the outside tool in

upper fork bar as shown in figure 4-92. Hold the

position.

4-62

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |