|

|||

|

|

|||

|

Page Title:

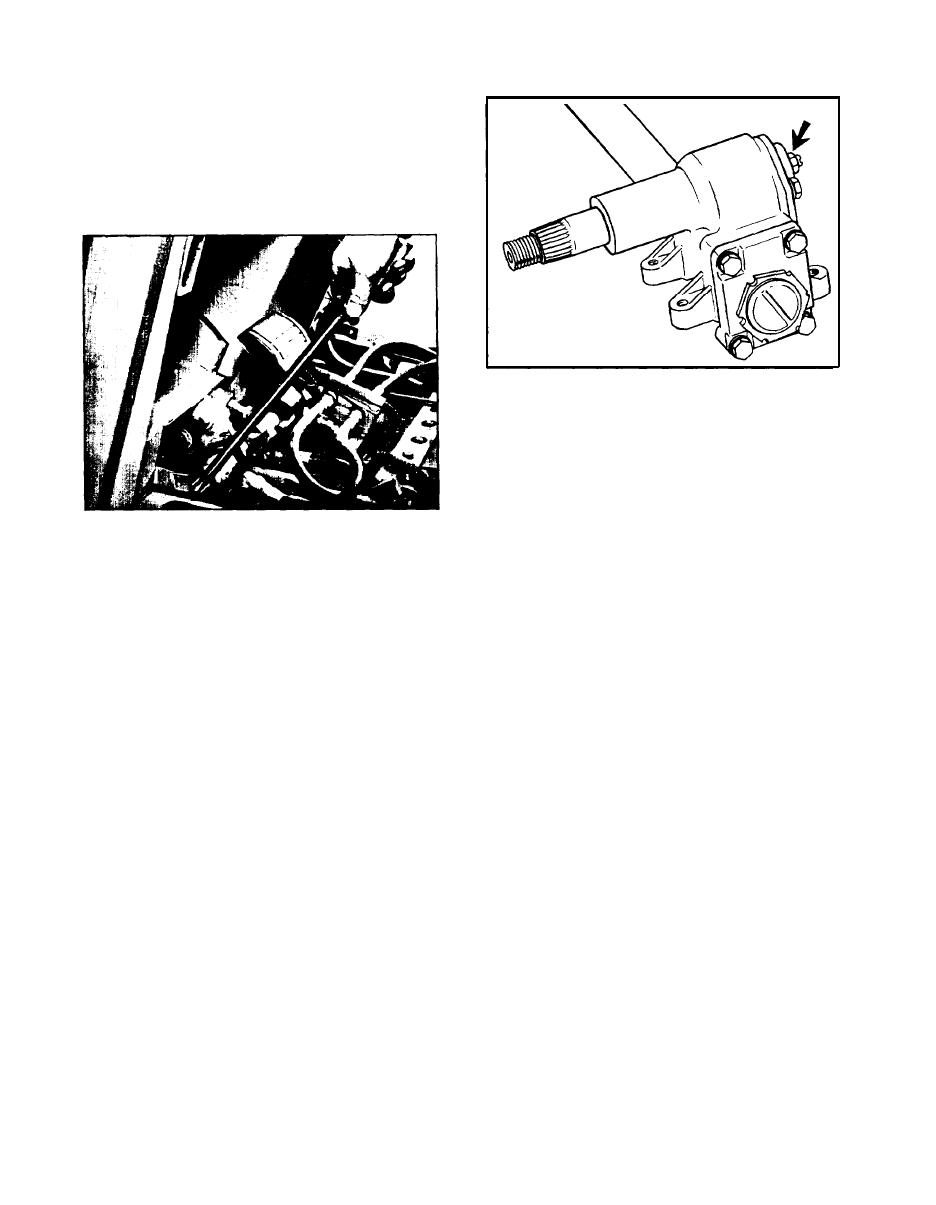

Typical Pitman Arm Shaft Locknut Torque |

|

||

| ||||||||||

|

|

NOTE

In some cases the pitman arm may barely contact

the stops when the hand wheel is fully turned

In such cases it i s not necessary

right or left.

to reposition the pitman arm on the shaft, since

final adjustment of the pitman arm stops will

c o r r e c t this condition.

Typical Sector Lash

9846.

Adjustment Screw

If the pitman does not move instantly

12.

loosen the jam nut on the sector lash ad-

....

justment screw (H) and turn the adjustment screw

in until all free play between the hand wheel

and pitman arm is eliminated. T h e n . . . . t i g h t e n

the jam nut,

reconnect the front drag link

Typical Pitman Arm Shaft

9848.

(1) to the pitmen are. Torque the front drag

Locknut Torque

link ball stud adjusting screw (J) to 18-22

pound feet, and back if off to the nearest hole,

9. Torque the pitman arm shaft locknut

i n s t a l l cotter pin.

(I tern D) 105-130 pound feet....even when you

haven' t had to reposition the pitman arm.

14. Be sure cylinder piston rod stroke

is centered so that piston does not bottom out

10. With the pitman arm (E) and steering

i n either direction.

gear centered., . . next check for free play between

the hand wheel and pitman arm....by turning the

15. With the cylinder and steering gear

hand wheel. The pitman arm should move the instant

centered, the steer wheels should be straight.

the hand wheel moves,

I f they are not... it will be necessary to adjust

the rear drag I ink (K) as we check out the link-

11. Then.... center the steering gear by

age.

turning the hand wheel (F) full right to full

l e f t . . ..counting turns from right to left and

bringing the hand wheel back to its halfway

p o s i t i o n . When installing the hand wheel . . . .

torque the hand wheel nut (G) to 35 to 40 pound

f e e t . . . . a n d , using a prick punch, stake the nut

t o t h e s h a f t . . . . in two places 180 degrees apart.

If the hand wheel has three evenly spaced spokes

. . . . then spoke position can be disregarded.

4-46

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |