|

|||

|

|

|||

|

Page Title:

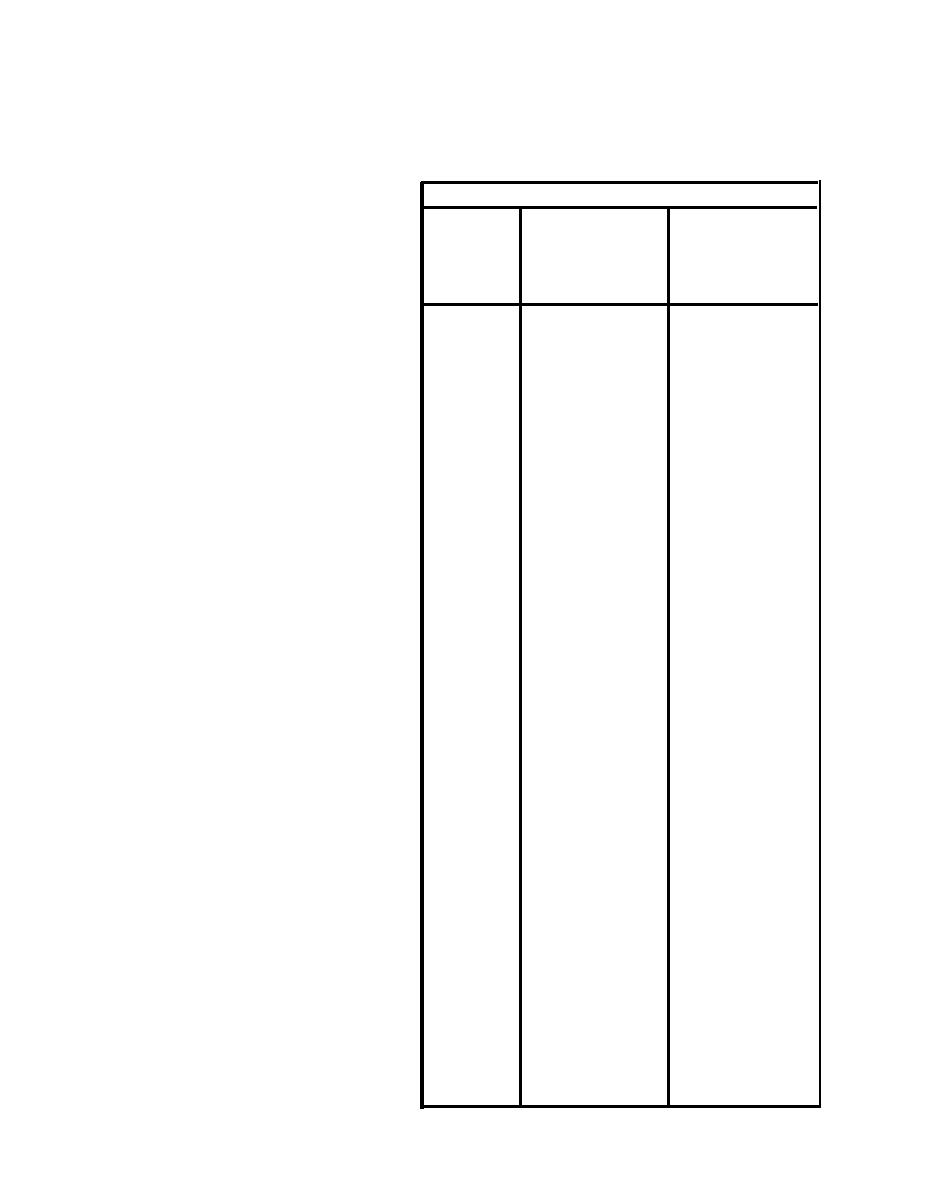

TABLE 3. PREVENTIVE MAINTENANCE INSPECTION |

|

||

| ||||||||||

|

|

TABLE 3. PREVENTIVE MAINTENANCE INSPECTION

I N S P E C T I O N INTERVAL

Annual,

3 months or 300

DRY,

or 1200

operating hours,

When

operating hours,

whichever

used

whichever

comes first

comes first

AXLES

X

Check and tighten wheel driving flange bolts.

X

Check security of axle mounting to frame.

X

Check differentials for oil leaks.

Check differential and drive axle

X

planetaries oil level.

BATTERY

X

Check specific gravity.

X

Check electrolyte level.

Check terminals and cables for

X

corrosion and tightness.

B R A K E S - SERVICE

X

Check brake lines for leaks.

X

Check brakes for proper operation.

X

Inspect linings for wear.

X

Check brake pedal for excessive travel.

BRAKES - PARKING

X

Check linkage for wear.

X

Check linings for wear.

X

Check for proper operation.

X

Check coolant level in radiator

X

Check anti-freeze protection.

X

Check coolant color and cleanliness.

X

Check all hoses and connections for leaks.

Check water pump inlet and outlet

X

connection for leaks.

X

Flush coolant system.

Check radiator for leaks, and mounting

X

for security.

Check thermostat operation, and housing

X

for tightness.

4-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |