|

|||

|

|

|||

|

Page Title:

Section IV. PERIODIC INSPECTION, MAINTENANCE AND LUBRICATION |

|

||

| ||||||||||

|

|

SECTION IV

PERIODIC INSPECTION, MAINTENANCE

AND

LUBRICATION

4-1. SPECIAL TOOLS.

indicates proper lubricants to be used in servicing

the truck, the points of application, and the

4-2. Special tools required for the performance of

maximum intervals for performance of lubrication

inspection, maintenance and testing of the truck

services. Adjust lubrication intervals to some

and its components are listed in Table 2.

shorter periods if extreme climatic conditions or

severity of service require more frequent attention

4-3. PERIODIC INSPECTION.

to lubrication.

4-4. A periodic inspection schedule must be

4-6. Access to the engine compartment is gained

established and maintained in accordance with the

by depressing spring latch in the side panel,

information given in Table 3. Intervals specified are

opening side panels on each side of the truck, and

m a x i m u m periods permissible and are based on

raising seat support as shown in figure 4-2.

optimum service conditions. Adjust inspection

intervals accordingly if extreme

climatic or

operating conditions exist for any extended period

are determined primarily by the service conditions

of truck operation.

under which the vehicle operates. The condition of

the filter element should be checked every 8 hours

4-5. PERIODIC SERVICE AND LUBRICATION.

and cleaned every 50 hours as a minimum.

Refer to figure 4-1 for the lubrication chart, which

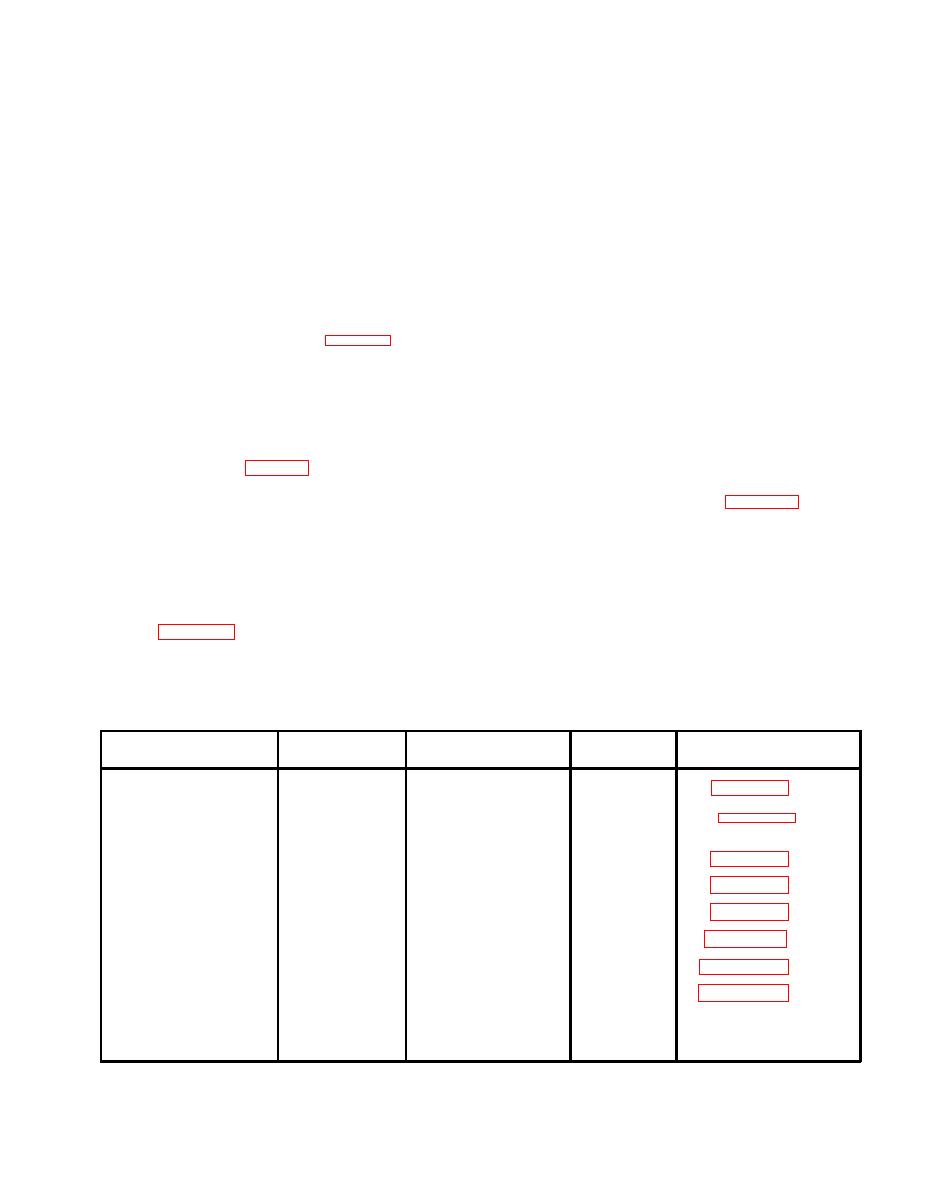

TABLE 2. SPECIAL TOOLS FOR INSPECTION AND MAINTENANCE

Nomenclature

Part/Model No.

Manufacturer

Range

Application

Cooling System Tester

4-17 psi

Stant Manufacturing

See para. 4-13

Expanded Scale

260

Simpson

0 - 5 0 volts

See paras. 4-34 & 4-35

Fluid-Bal

Pressure Bleeder

Wagner-Electric

0-30 psi

See para. 4-20

Compression Gage

0-300 psi

See para. 4-40

Distributor Tester

Sun

See para. 4-45

Vacuum Gage

0-30 in. hg.

See para. 4-51

Hydraulic Pressure

Quadrigage

0-3000 psi

Mico Manufacturing

See para. 4-65

Hydraulic Circuit

HSD

0-3000 psi

Schroeder

Brothers

Tester

0-30 GPM

0-240F.

4-l

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |