|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

The

reduce arcing and current leakage.

When the engine has obtained normal

distributor features automatic spark

operating temperature the choke valve

advance through the action of centrifugal

(25) must be fully opened to assure

force on the advance weights. The 12

maximum power and economy. In addi-

volt automative type coil is mounted just

tion, extended use of the choke re-

forward of the distributor in a bracket

sults in more gasoline being supplied

attached to the left side of the engine.

to the engine than can be burned. A

large percentage of the unburned gas-

ALTERNATOR. The alternator is a

1-39.

oline is lost through the exhaust

12 volt, 32 ampere unit mounted on an

system. The remainder of the raw

adjusting bracket to the side of the

gasoline is forced between the pistons

engine and driven by a V-belt.

and cylinder walls, washing away the

protective oil film and increasing

engine wear, and enters the crankcase

where it dilutes the engine oil.

Any adjustments that are necessary on

the carburetor should never be attempted

until the engine has obtained its normal

operating temperature and the choke valve

(25) has been placed in the wide open

position.

STARTER MOTOR. The starting motor

1-36.

is bolted to the engine flywheel housing

on the right underside of the vehicle.

The motor is a two pole, four-field, 12

volt unit which cranks the engine when

the pinion drive is engaged to the fly-

wheel ring gear. An electrical inter-

lock prevents starter engagement when

the engine is running.

STARTER SOLENOID. The starter

1-37.

solenoid is bolted to the starter drive

housing and serves two functions; that

of engaging the starter pinion to the

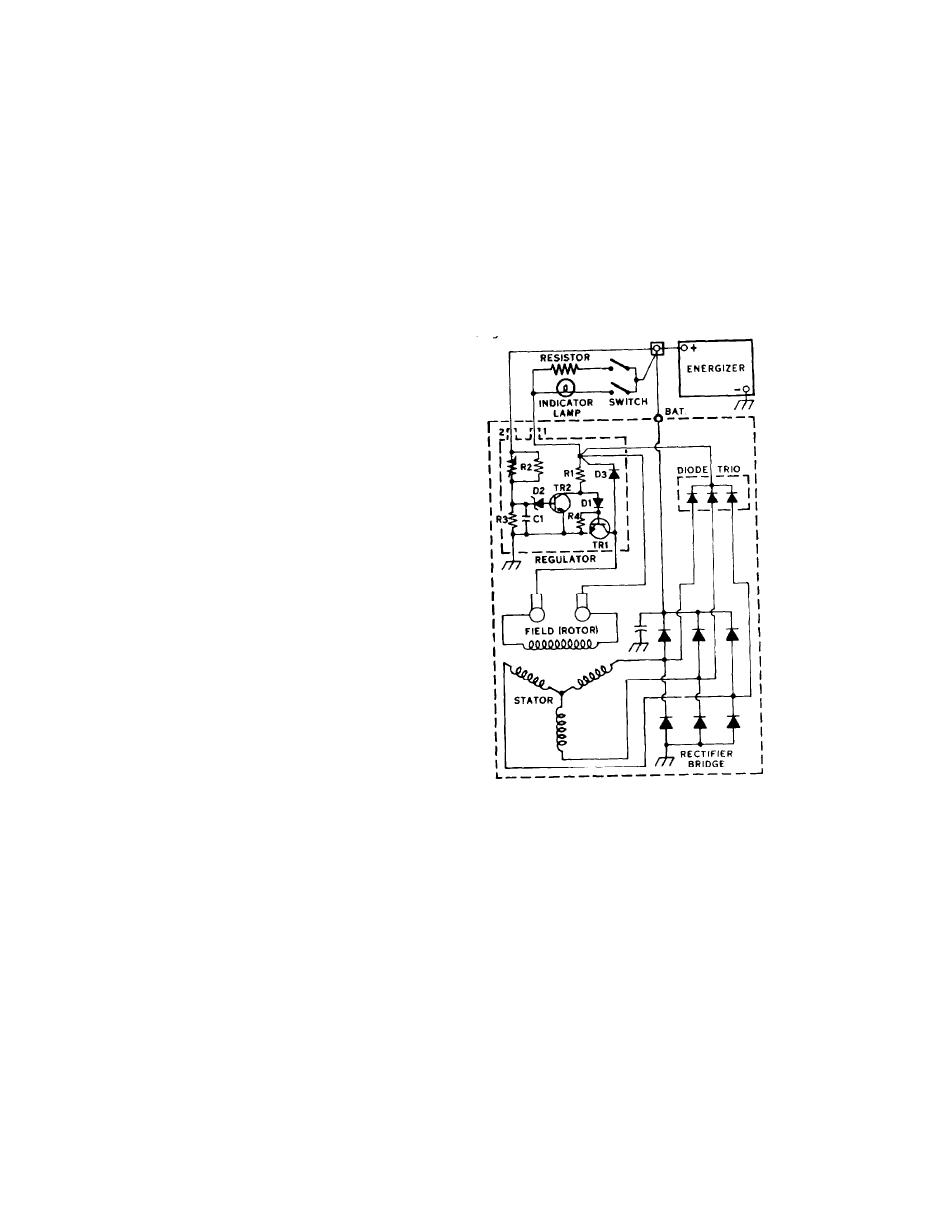

Typical 10-SI Wiring Diagram.

flywheel ring gear, and acts as a

switch to close the circuit between the

Basic principles of operation are as

The solenoid

battery and starter motor.

follows:

becomes energized when the ignition

switch mounted on the dash is held in

When the SWITCH is closed, current from

the start position.

the ENERGIZER follows through the

A M M E T E R and the RESISTOR to the

IGNITION DISTRIBUTOR AND COIL.

1-38.

generator no. 1 terminal (at top of

The single point set 'distributor is

REGULATOR), t h r o u g h r e s i s t o r R 1 , d i o d e

located on the left side of the engine

Dl, and the base emitter of transistor

and is driven by the oil pump shaft.

TR1 to ground, and then back to the

This location provides easy access for

ENERGIZER. The ammeter is then

service. The distributor shaft features

energized. The resistor in parellel

offset drive gear which makes improper

with the ammeter reduces total

assembly impossible. The distributor

circuit resistance to provide higher

cap is molded of an alkyd material to

field current for initial voltage

buildup when the engine starts.

1-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |