|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

Because the size of the power jet

(20) and the position of the

power adjusting needle (18)

restrict the amount of fuel which

can enter the nozzle (14), the

fuel in the accelerating well

(16) will soon be exhausted and

air will then enter through the

nozzle air bleeds (15) to mix

with the fuel passing through the

nozzle

(14).

The

amount

of

air

that can enter into the nozzle

(14) is limited by the size of

the nozzle air vent (21).

The result of air bleeding into

the nozzle (14) is, to help

atomize or break up the fuel into

finer particles, to regulate the

quantity and rate of discharge of

fuel fed from the accelerating

we11 (16), during acceleration,

and to provide correct mixture

proportions for full throttle

operation.

As the throttle valve is opened toward

the wide open position the velocity

through the venturi (17) continues to

increase,

lowering

the

air

pressure

at

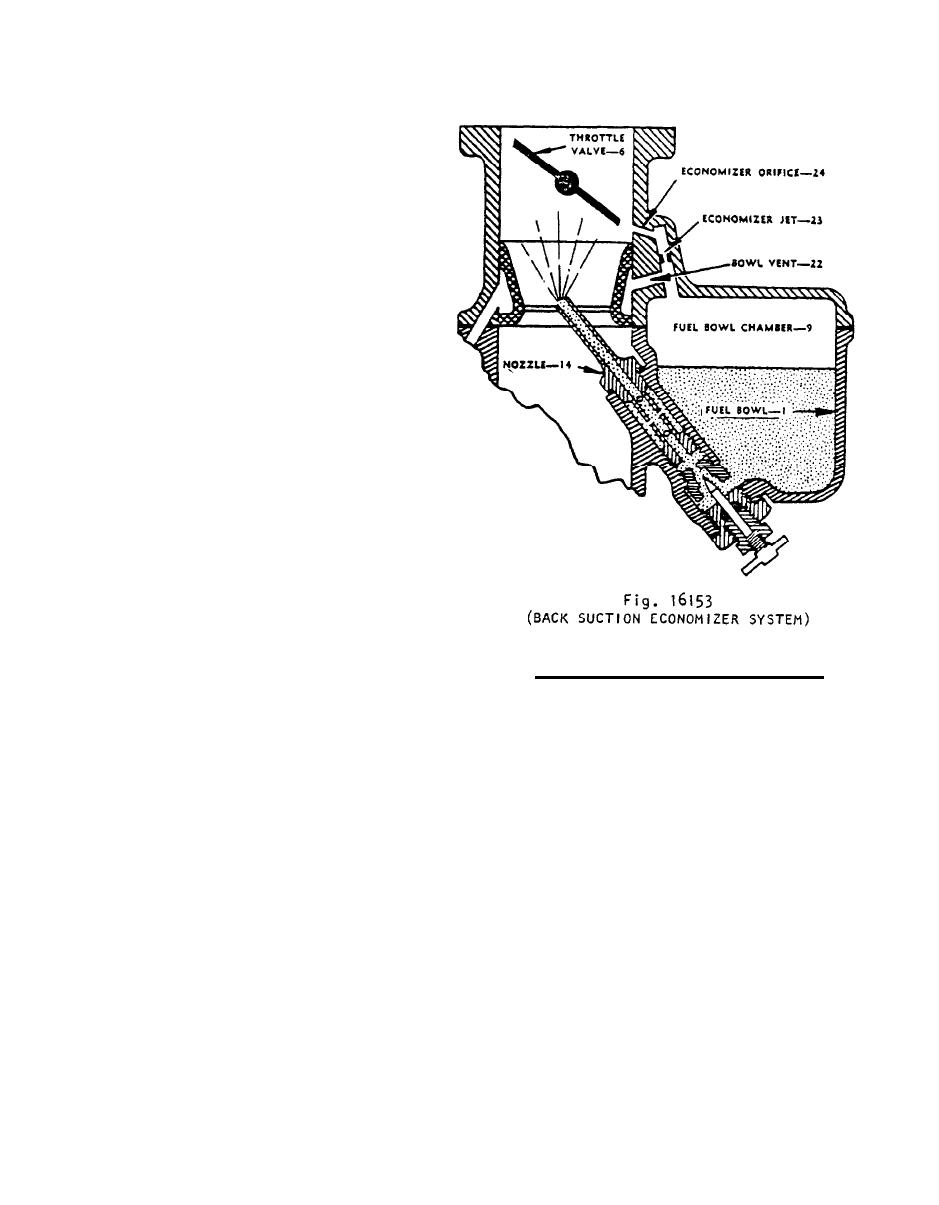

d. BACK SUCTION ECONOMIZER SYSTEM:

the nozzle (14) and resulting in

additional fuel being supplied to the

engine as the speed is increased.

The amount of fuel supplied to an engine

is controlled by the size of the power

When the throttle valve (6) is opened

jet, the position of the power adjusting

suddenly from slow or just off slow

needle, and the difference in air

idle position, the fuel stored in the

pressure between the fuel bowl chamber

accelerating well (16) is forced out

and the venturi. However, in many

through the nozzle air bleeds (15) very

engines the mixture must be leaned out

rapidly and serves to provide the extra

additionally during part throttle

richness required by the engine to meet

operation to obtain maximum economy. To

the sudden load.

When the throttle

provide this leaner mixture Marvel-

valve (6) is closed, fuel again fills

Schebler Tractor and industrial

the accelerating we11 (16), ready for

C a r b u r e t o r s m a k e u s e o f t h e "B a c k

the next acceleration.

S u c t i o n E c o n o m i z e r S y s t e m ". W i t h t h i s

method of metering fuel, air pressure

in the fuel bowl chamber is regulated

and controlled according to load

conditions by a combination of bowl vent

and economizer passages communicating

with throttle bore of the carburetor.

1-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |