|

|||

|

|

|||

|

Page Title:

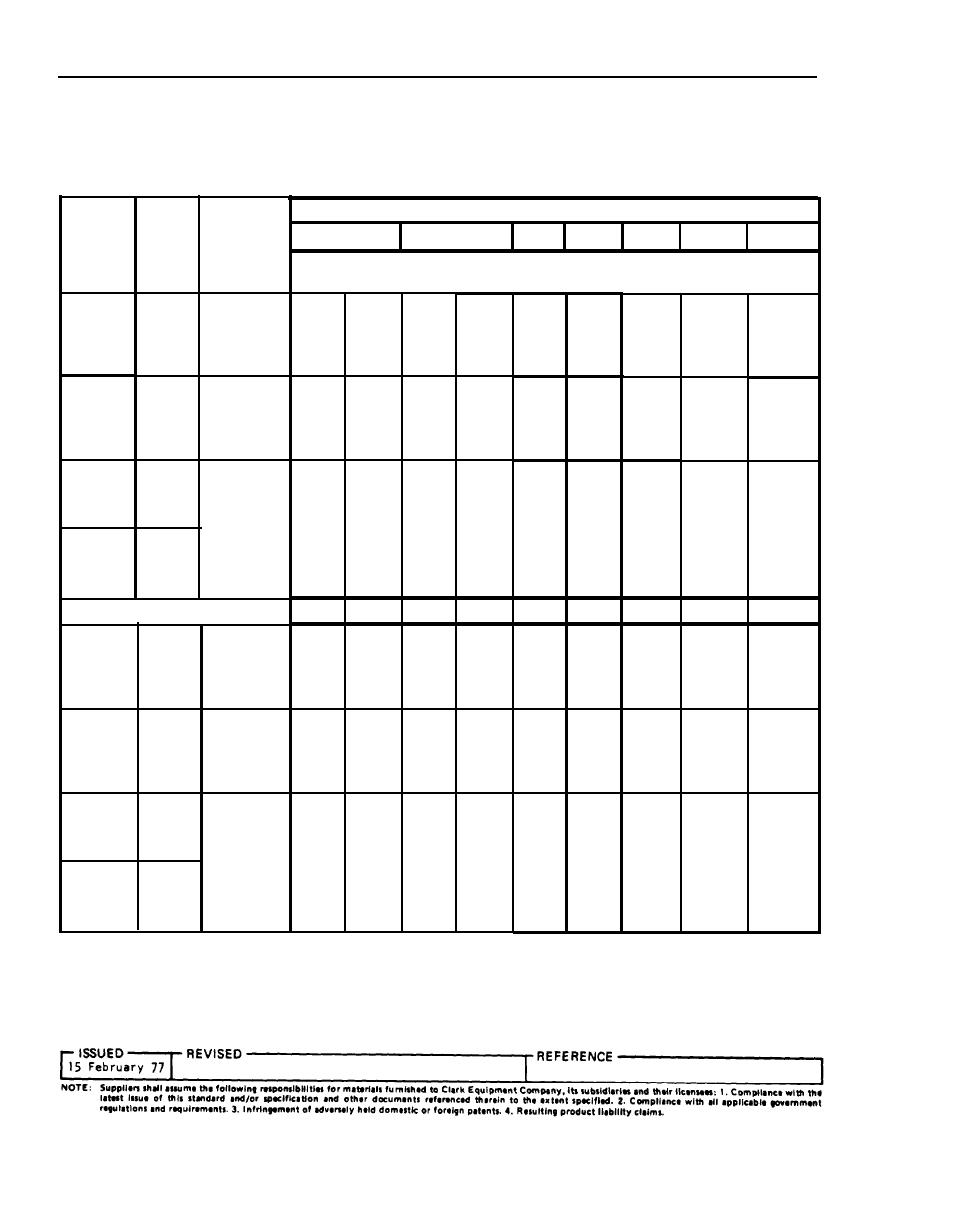

TIGHTENING TORQUE VALUES FOR STEEL THREADED FASTENERS |

|

||

| ||||||||||

|

|

Engineering

DATA SHEET 36

Standards

PAGE 1 OF 2

TIGHTENING TORQUE VALUES FOR STEEL THREADED FASTENERS

The following torque values are for use in general applications and where torque values are not otherwise

specified. They are not limited to parts covered by the reference Clark standards, which are examples only,

but apply to all steel screw threaded fasteners having the same strength levels and coated as specified

herein.

TENSILE

COARSE

SCREW OR BOLT NOMINAL THREAD SIZE, INCH

(NUT PROOF)

AND

REF

STRENGTHS,

FINE

CLARK

0.625

0.500

0.5625

0.4375

0.375

0.3125

0.875

0.250

0.750

PSI

TREADED

STDS

[MPa],

FASTENERS

TIGHTENING TORQUE, LB,FT, MAXIMUM * LB.IN

MINIMUM

[N-m] MINIMUM

[N-ml

45

70

28

1C-2C

120 000

90 *

200 *

140

CAP

100

245

360

[38]

[61]

[95]

SCREW,

[10]

[23]

[490]

[135]

[190]

[330]

15C-16C

BOLT

[825]

65

40

80

25

AND

180

220

125

330

[34]

[88]

[54]

610-62D

SAE GRADE 5

NUT

[9]

[21]

[l70]

[170]

[300]

[450]

100

40

65

120 *

240 *

CAP

150 000

17C-18C

140

190

525

330

[135]

[54] [88]

I

SCREW,

[14]

[27]

[190]

[450]

[260]

[710]

23C-24C

BOLT

[1030]

90

60

35

110

AND

215

300

125

175

475

[48] [82]

[125]

NUT

63D-640

SAE GRADE 8

[13]

[24]

[170]

[240]

[410]

[645]

SOCKET

25C-26C

HEAD

75

50

145 *

300 *

120

400

CAP

165

230

650

73G-74G

[68]

160 000

[102]

SCREW

[16]

[34]

[160]

[225]

[310]

[540]

[880]

45

70

110

[1100]

12 POINT

210

600

130

270

150

360

[61]

HEAD

[15]

[31]

[95]

[815]

[150]

[285]

[490]

[205]

93G-94G

CAP

SCREW

2.000

1.000

1.125

1.250

1.500

1.625

1.750

1.875

1.375

1000

1650

CAP

1C-2C

105 000

2200

4200

525

1350

3500

720

2750

[2240]

SCREW,

[1830]

[975]

[1360]

[2980]

[3730]

[4750]

[5700]

[710]

15C-16C

BOLT

[725]

1200

AND

1500

2000

2500

3800

475

650

900

3150

NUT

61D-62D

SAE GRADE 5

[1220]

(2040]

[880]

[1630]

[645]

[2720]

[3390]

[4270]

[5150]

800

1625

2200

17C-18C

CAP

150 000

2850

4800

3800

6100

7200

1175

SCREW,

[1600]

[2200]

[1085]

[2980]

[3870]

[5150]

[6500]

[8300]

[9800]

23C-24C

BOLT

[1030]

1050

2000

2600

4300

AND

6500

725

5500

1475

3450

63D-64D

[2000]

NUT

SAE GRADE 8

[4680]

[8800]

[985]

[1425]

[2720]

[3530]

[5830]

[7450]

-

-

25C-26C

SOCKET

HEAD

8600

1000

1450

2000

CAP

2700

4600

7200

3450

73G-74G

5700

160 000

[4680]

[6240]

[11 700]

SCREW

[1360]

[1970]

[2720]

[3660]

[7730]

[9800]

12 POINT

1300

1850

2450

[1100]

900

4150

5100

6500

7800

3150

[1220]

HEAD

[8800]

[10 600]

[1770]

[2510]

93G-94G

[3330]

[4270]

[5630]

[6920]

CAP

SCREW

NOTES:

1. Torque values shown represent results of extensive laboratory testing, field experience and study of

accumulated supplier data on various types of cap screws coated with zinc phosphate and oil in accordance

with Clark Protective Treatment specification H and used with hardened plain or H coated washers, such as

covered by Clark standard 27E.

viii

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |