|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

in the wheel, and press or drive the cups into

their bores. Cups must be square with the

bores, and fully seated at installation.

2. Lubricate the inner wheel bearing cone with

specified grease. Use an applicator designed to

force lubricant into the bearing rollers.

3. Position inner bearing cone on the spindle.

Lubricate the bearing cups in the wheel and

carefully install the wheel on the spindle.

4. Lubricate the outer bearing cone with the

specified lubricant, using an applicator. Install

the bearing cone on the spindle.

5. Install washer and retaining nut on spindle.

While rotating steer wheel, tighten retaining nut

to a torque of 50 lb-ft; then back off nut until

loose (0 lb-ft). Rotate wheel alternately in each

direction while tightening retaining nut until a

torque of 25 lb-ft is obtained. Then back off nut

30 min to 60 max and install cotter pin.

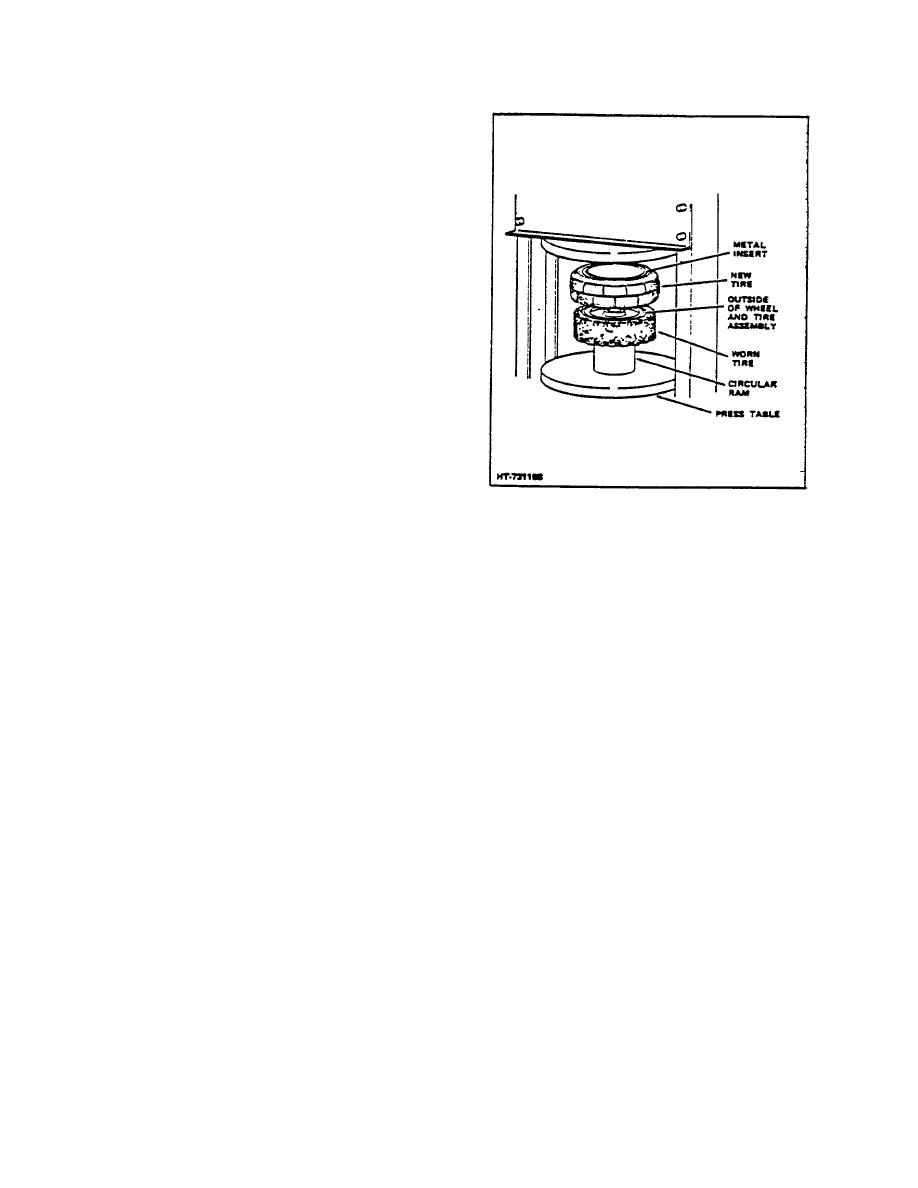

Figure 36. Cushion Tire Replacement

6. Install hu b cap and secure with capscrews and

lockwashers, tightening capscrews securely.

of new tire. Remove any scale or rust with

sandpaper. Clean inside of metal insert and

7. Raise vehicle slightly with the hoist and remove

lubricate it with bearing grease.

the wooden blocks from under the frame. Then

lower vehicle so steer wheels rest on the floor.

3. Plac e a circular ram (Fig. 37) on the press table.

Remove hoist from rear of vehicle.

The length of the ram must be longer than the

width of the old tire that is to be removed to

D. CUSHION TIRE REPLACEMENT

allow complete removal of old tire. The outside

diameter of the ram must-be small enough to fit

The wheels used on all cushion tire lift trucks are

loosely in the insert of the tire, but must be large

machined from castings. Any misalignment of the tire

enough to rest squarely on the flat surface at the

and wheel, while the tire is being pressed onto the

outer edge of the wheel.

wheel, can cause possible damage to the wheel.

Because of this, a chamfer has been provided on the

4. If the outside edge of the wheel is not flush with

outside edge of the wheel and on the end of the inside

the edge of the metal insert in the old tire,

diameter of the tire's metal insert. The chamfers help

measure how far wheel is recessed inside the

center the wheel and tire during the pressing operation

tire. New tire must be replaced at the same

and reduce the possibility of misalignment.

position that worn tire is installed on the wheel.

A spacer, slightly smaller in diameter than-the

CAUTION

inside diameter of the tire insert and the same

To prevent damage to the wheel, the

thickness as the depth of recess, can be used to

tire must be installed with the

obtain the proper amount of recess.

chamfered side of the wheel up.

5. Position wheel assembly with worn tire on top of

To replace cushion tire, perform the following:

circular ram so outside of wheel is positioned

upward. The outside edge of the wheel has a

1. Remove Wheel and tire assembly from lift truck.

chamfer to help guide the new tire onto the

wheel. The chamfered edge must always be the

2. Check inside diameter of metal insert

leading edge of the wheel whenever a tire is

pressed onto a wheel.

3-178b

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |