|

|||

|

|

|||

|

Page Title:

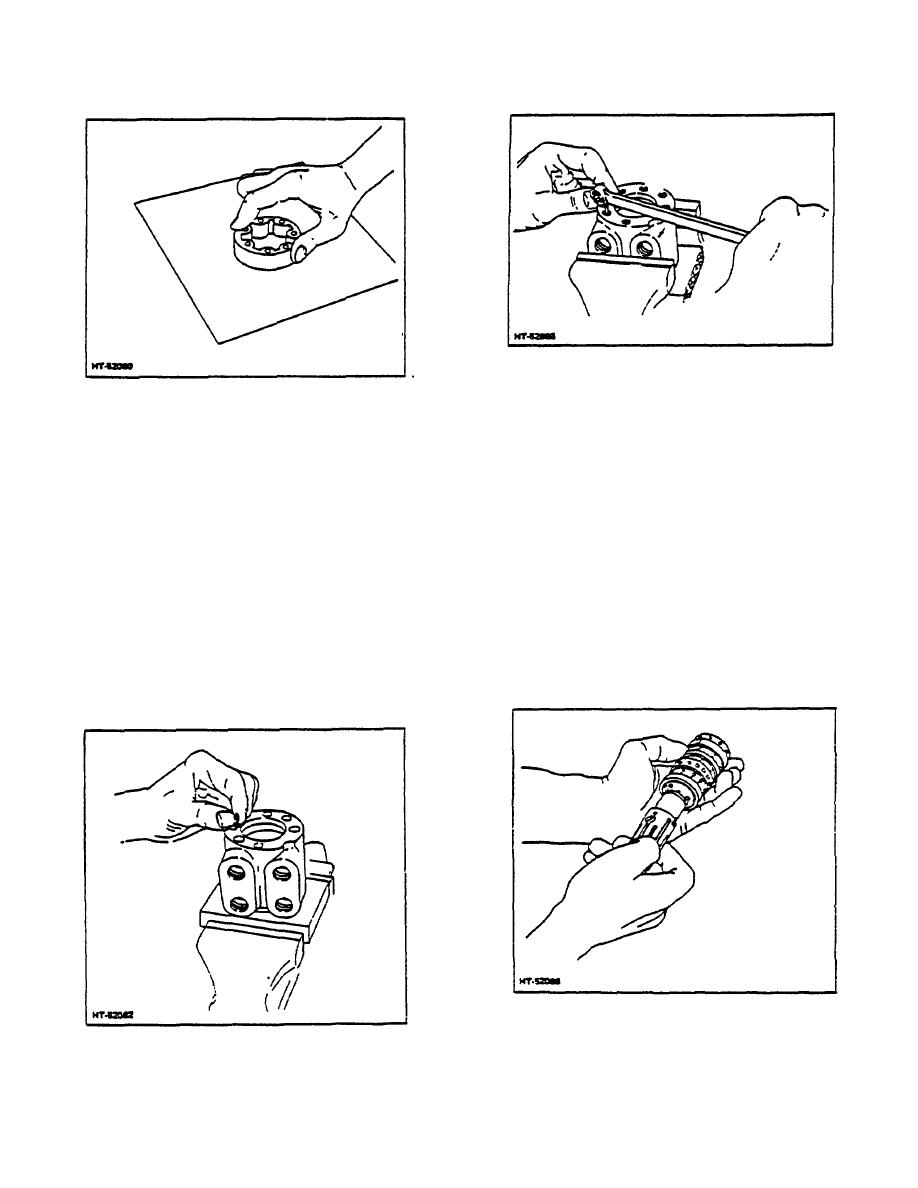

Figure 18. Polishing the Ring Gear |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

Figure 20. Tightening Check Valve Seat

Figure 18. Polishing the Ring Gear

NOTE

Tool is available as part number

Rotate spool carefully while

sliding

parts

600057 from Char-Lynn Company,

together. Test for free rotation.

15151 Highway S, Eden Prairie,

Minnesota, 55343.

CAUTION

Spool must rotate smoothly in sleeve

7. Compress extended end of centering spring set

with finger tip force applied at the

and push it into spool-sleeve assembly,

splined end.

withdrawing installation tool at the same time.

8e sure the spring set is centered in the parts so

6. With spring slots of the spool and sleeve in line,

they can be pushed down evenly and flush with

stand parts on end and insert spring installation

the upper surface of the spool and sleeve.

tool through slots in both parts (Fig. 22).

Position 3 pairs of centering springs (or 2 sets of

8. Install the cross pin through the spool assembly

three each) on bench so that extended edge is

and push into place until cross pin is flush or

down and arched center section is together. In

slightly below the sleeve

this position, enter one end of entire spring set

into spring Installation tool.

Figure 21. Installing Spool in Sleeve

Figure 19. Installing Check Valve Spring

3-167

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |