|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

C. BRAKE DRUM INSPECTION

Original I.D.

Maximum

of

Machined

1. On out-of-round drums.

gauge diameter or

Brake Drum

I.D.

radius at points 45 apart around inside

11.000" to 11. 010"

11. 060"

circumference of drum.

Drum should be

13.125" to 13. 133"

13. 185"

resurfaced if measurement differences are

13.135" to 13. 143"

13. 195"

greater than 010" on diameter, or . 005" on the

14.250" to 14. 260"

14. 310"

radius.

D. BRAKE SHOES AND LINING

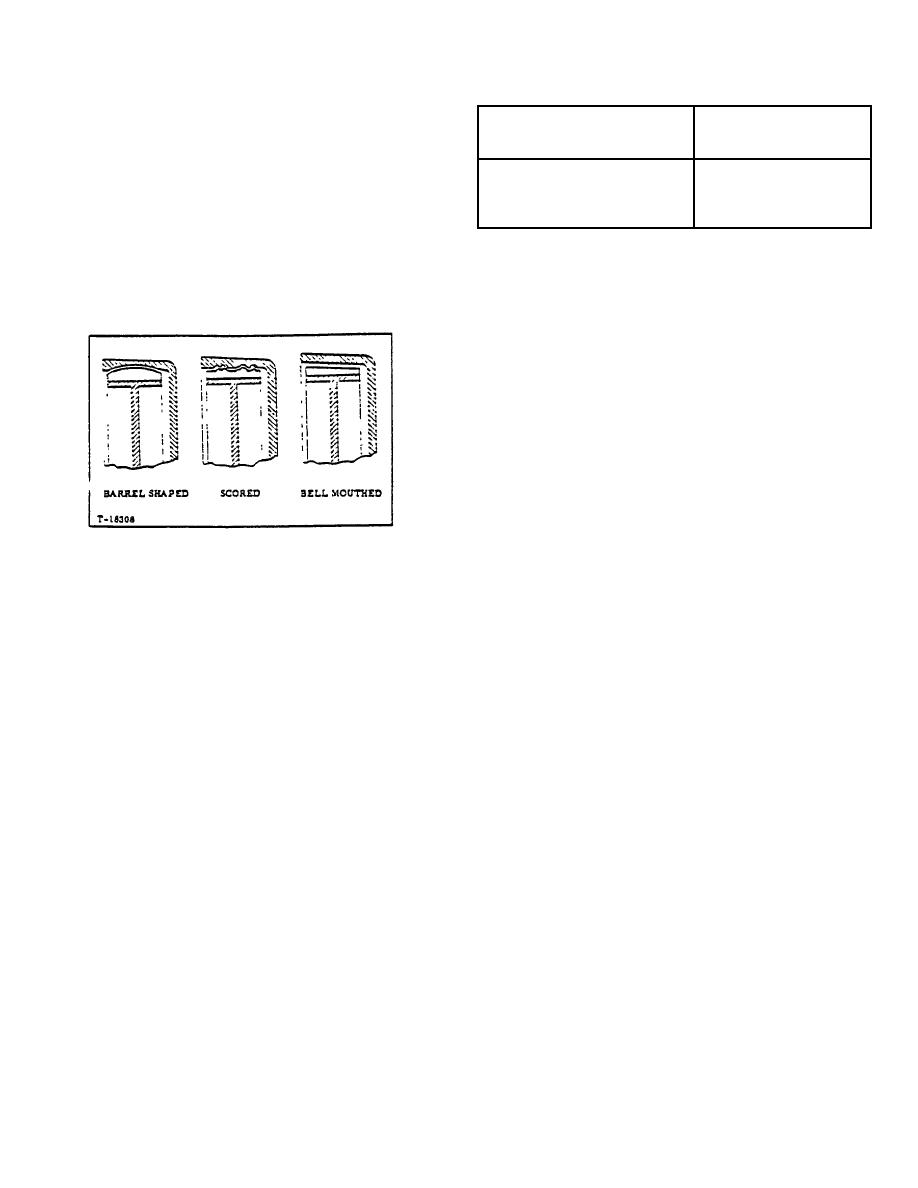

2. If worn lining face is tapered coward one side, or

worn more ca the sides than at the centers,

The brake shoes employ bonded lining. When lining

drum may be bell mouthed or barrel shaped.

replacement becomes necessary, it is recommended

that the brake shoes Ire replaced. Replace brake shoes

when any of the following have occurred:

1. Drums are resurfaced.

2. Lining is worn to shoe table.

3. Grease or hydraulic fluid soaked linings, causing

brakes to-grab or pull to one side.

4. If difficulty in stopping is traced to linings.

5. Fade is traced to severely charred or burned

linings.

Figure 4. Improper Lining Wear

NOTE:

3. Check drum surfaces as indicated by wear

Minor

charring

is

sometimes

pattern. Examine for scoring and heat checking.

remedied by buffing with sandpaper

If not scored over 010", tiling will wear in and

or grinding.

seat after some use. Heat checked or scored

drum should be replaced or resurfaced,

6. Lining Ls scored too deeply to be reworked by

depending upon extent of damage.

grinding

4. If drum does not require resurfacing, polish with

7. Brake shoe table Is worn, twisted or out -of-

fine emery cloth to remove discolorations and

round.

old lining residue adhering to surface.

8. Shoe is cracked. For brake shoe removal, refer

5. If drum requires resurfacing, always resurface

to following Paragraph E, DISASSEMBLY.

both drums to equal diameter. Finish grind or

hone drums to remove cutting tool marks,

CAUTION

otherwise linings will wear rapidly and brake

Whenever handling brake shoes, be

shoes will "runout" when brakes are applied and

careful act to get grease or dirt on

will release with a clicking noise.

brake linings as serious damage may

result.

CAUTION

Never use a drum machined to a

Dirt or grease on brake linings (not grease soaked) may

diameter greater than . 050" original

be remedied by buffing with sandpaper or grinding.

size.

Thin drums are subject to

Clean shoes with compressed air and dry cloth to

excessive

heat

expansion

and

prevent damaging shoes or Linings.

flexing. causing fade and spongy

pedal. They also could break under

E. DISASSEMBLY

strain of severe use.

(Refer to

following chart. )

To disassemble brake assembly proceed as follows:

3-149

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |