|

|||

|

|

|||

|

Page Title:

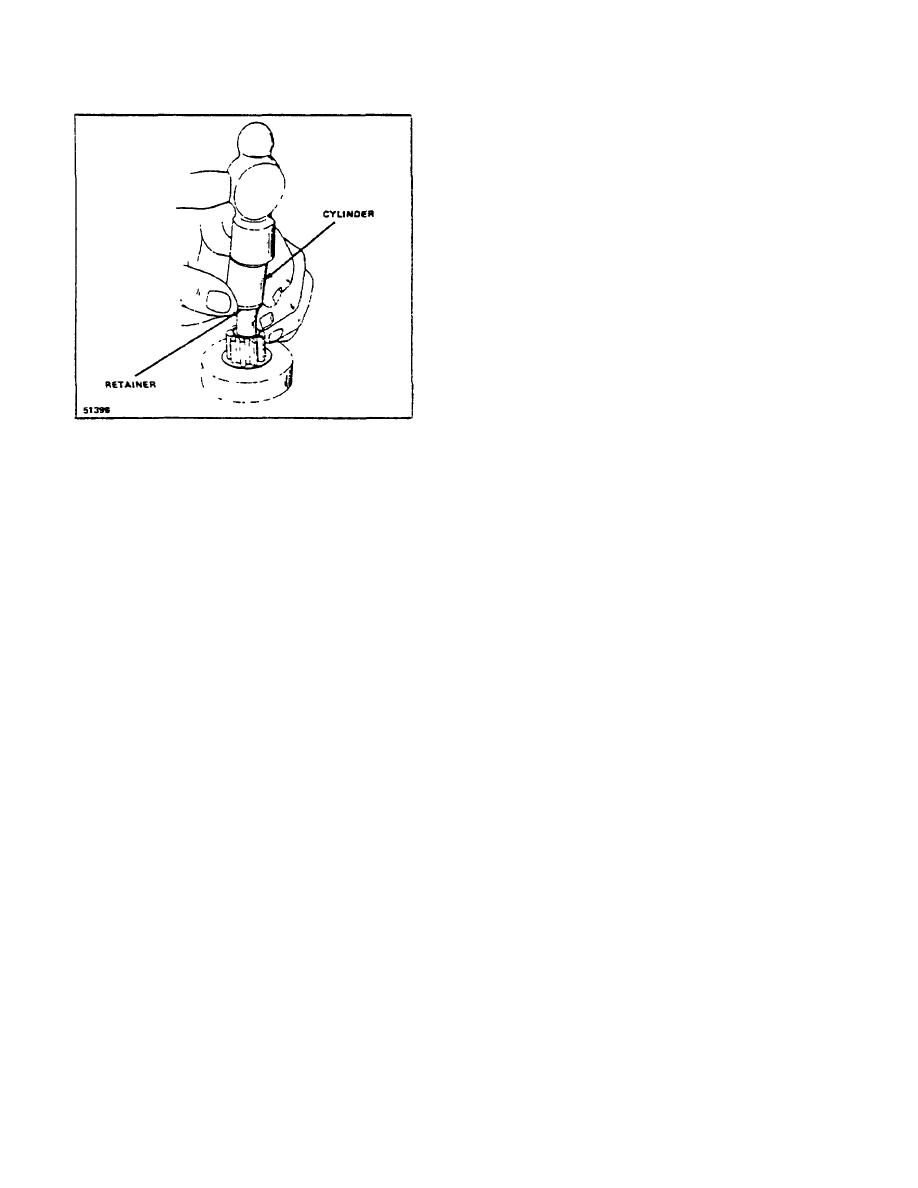

Figure 3-4. Removing Retainer from Snap Ring |

|

||

| ||||||||||

|

|

TM 10-3930-644-14 & P

If the commutator is worn, dirty, out of round, or

has high insulation, the commutator should be

turned down and undercut as previously

described.

3. Field Coils

The field coils should be checked for grounds

and opens using a test lamp.

a. To chec k for grounds, disconnect the field

coil ground connections. Connect one

test prod to the field frame and the other

to the field connector. If the lamp lights,

the field coils are grounded and must be

repaired or replace.

b. To check for opens, connect test lamp

prods to ends of field coils. If lamp does

not light the field coils are open.

Figure 3-4. Removing Retainer from Snap Ring

If the field coils need to be removed for repair or

2. Armature

replacement, a pole shoe spreader and Pole

shoe screwdriver should be used. Care should

The armature should be checked for short

be exercised in replacing the field coils to

circuits. opens and grounds.

prevent grounding or shorting them as they are

tightened into place. Where the pole shoe has a

a. check armature for shorts by placing it on a

long lip on the side, it should be assembled in

"growler", and with a steel strip or a hack saw

the direction of armature rotation.

blade held on armature core, rotate armature. If

blade vibrates, armature is shorted in area of the

H. REASSEMBLY

core below the vibrating blade. Copper or brush

dust in slots between communicator bars

1. Place the clutch assembly on the armature

sometimes causes shorts which can be

shaft. To facilitate replacing the -nap ring and

eliminated by cleaning out slots. Shorts or

retainer onto the armature.

crossovers of coils at core end can often be

eliminated by bending wire slightly and

a. Place the retainer on the armature shaft

reinsulating exposed bare wire. If short cannot

with the -upped surface facing the snap

be eliminated armature must be replaced.

ring groove.

b. Opens may be located by inspecting the points

b. Place the snap ring on the end of the

wire the conductors are Joined to the

shaft. With a piece of wood on top of it,

commutator for loose connections.

Poor

force the ring over the shaft with a light

connections cause arcing and burning of the

hammer blow (See Figure 3-5), then slide

commutator. If the bars are not badly burned,

the ring down into the groove.

resolder the leads in the riser bars and turn the

commutator down in a lathe. Then undercut the

c. To force the retainer over the snap ring,

insulation between the commutator bars .031".

place a suitable washer over the shaft and

squeeze retainer and washer together

c. Grounds in the armature can be detected by the

with pliers (See Figure 3-6).

use of a test lamp. If the lamp lights when one

test prod is placed on the commutator and the

d. Remove the washer.

other test prod on the armature, the armature is

grounded.

2. Refer to the disassembly procedure and follow

in reverse to complete the reassembly.

R-146-1

3-95

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |