|

|||

|

|

|||

|

Page Title:

Checking Ring-to-Land Clearance |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

to the most heat and the least lubrication.

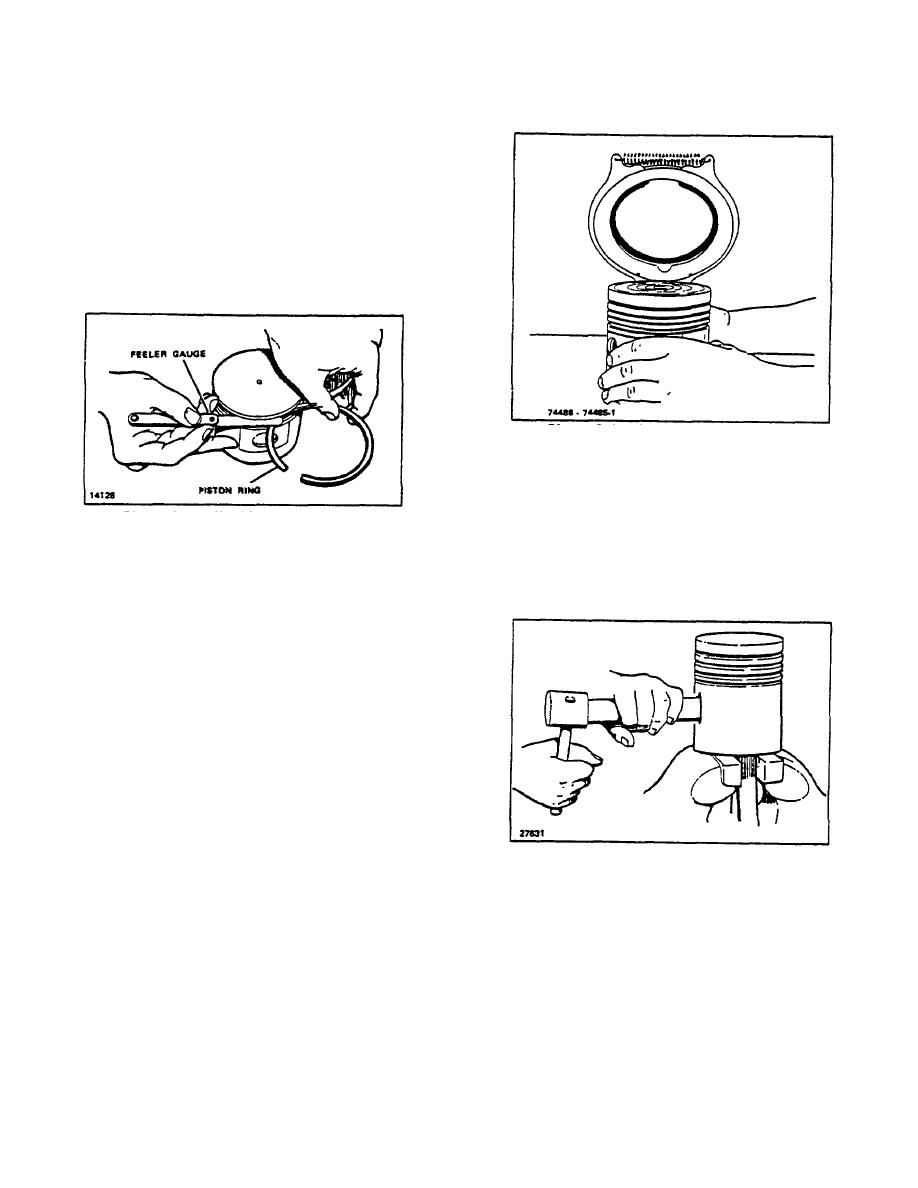

2. Checking Ring-to-Land Clearance

Piston ring side clearance must always be checked

when fitting rings to pistons which have been in

service (Figure 8-3). The object of the check is to

soot any pistons in which the ring grooves may have

worn excessively wide. A piston in this condition

must be replaced.

Figure 8-4. Removing or Installing Piston Rings

Using suitable tool remove piston pin retainer ring at

each end of piston pin.

Using a driving tool, drive piston pin from piston. Use a

wood block or brass drift as a driver (Figure 8-5). In

Figure 8-3. Checking Land-to-Ring Clearance

some instances it may not be necessary to drive piston

To check the side clearance, select a feeler gauge of

pin from piston. Specified clearance between piston and

pin at room temperature is .0002" to .0004" loose.

the maximum clearance specified. With the ring in

place, insert the feeler if possible between the ring

land and the ring held well back in the groove. If the

feeler slides in at any point, it indicates the clearance

is at or over allowable maximum. A snug fit of the

feeler suggests further consideration as to whether

the piston warrants reinstallation since the groove

wear may be at the top limit.

On all pistons passing the above check, make an

inspection for minimum clearance with a feeler gauge

of the specified minimum thickness. This feeler

should slide freely all around the groove as the piston

and ring are rotated.

D. CONNECTING RODS AND PISTON RINGS -

REMOVAL FROM PISTON

Figure 8-5. Removing Piston Pin from Piston

To avoid breaking piston rings, the use of a ring remover

A pin that is loose enough to drop through the piston by

and installer is recommended (Figure 8-4). Care must

its own weight is considered too loose. From a service

be taken not to overstress piston rings by spreading

standpoint, a fit of this kind, if not due to severely worn

ends more than is necessary to remove them from

parts, will cause an engine to be somewhat noisy but will

piston. Before removing rings, inspect for wear and side

not necessarily impair performance or reduce engine life.

clearance in grooves.

However, removal will be

If oversize pins are installed, do not forget to check the

necessary in order to clean carbon from grooves.

fit of the pin in the connecting rod bushing since the new

pin will be too snug in a standard rod.

R-104-1

3-28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |